Add to Cart

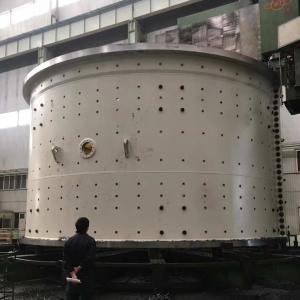

Zirconia Sand Stone Mineral 20mm Grinding Ball Mill High Capacity

| Model | Material | Grinding disc diameter | Roller number | Main motor power | Powder separator power | Input size | Processing capacity(t/h) | Annual capacity(kt) |

| JMML1700 | High calcium stone | 1700 | 2 | 200 | 30 | 20 <= | 12-15 | 80-100 |

| Slag | 1700 | 3 | 220 | 30 | 10<= | 8-10 | 60-70 | |

| Coal powder | 1700 | 2 | 200 | 30 | 40 <= | 10-20 | 100-200 | |

| JMML2500 | Raw material | 2500 | 2 | 710-900 | 45 | 65 <= | 60-90 | 430-700 |

| Coal powder | 2500 | 3 | 500-710 | 55 | 50 <= | 33-52 | 230-380 | |

| JMML2900 | Slag | 2900 | 3 | 1120 | 110 | 10 <= | 25-30 | 180-220 |

| Raw material | 2900 | 3 | 1100-1250 | 75 | 60 <= | 85-130 | 600-900 | |

| Clinker | 2900 | 4 | 1120 | 110 | 30 <= | 40-60 | 300-430 | |

| JMML3200 | Raw material | 3200 | 4 | 1400-1600 | 90 | 60 <= | 125-190 | 900-1360 |

| Slag | 3200 | 3 | 1600 | 132 | 5 <= | 40-50 | 300-360 | |

| JMML3600 | Raw material | 3600 | 4 | 1800-2240 | 110 | 65 <= | 150-260 | 1000-1800 |

| Slag | 3600 | 4 | 2500 | 160 | 5 <= | 65-80 | 460-570 | |

| Clinker | 3600 | 4 | 2500 | 160 | 5 <= | 70-85 | 500-600 | |

| JMML4600 | Raw material | 4600 | 4 | 2600-3300 | 150 | 85 <= | 250-350 | 1800-2500 |

| Slag | 4600 | 4 | 4300 | 300 | 5 <= | 110-130 | ||

| Clinker | 4600 | 4 | 4300 | 300 | 5 <= | 120-160 | 800-1100 | |

| JMML5000 | Raw material | 5000 | 4 | 3600 | 380 | 85 <= | 300-400 | 2100-2900 |

| Slag | 5000 | 4 | 5300 | 400 | 5 <= | 140-160 | 1000-1300 | |

| Clinker | 5000 | 4 | 5300 | 400 | 5 <= | 340-450 | 2000-3200 |

| Name | Zirconia Sand Stone Mineral 20mm Grinding Ball Mill High Capacity |

| Material | Zirconia Sand Stone |

| Attributes | Grinding Ball Mill |

Description:

1. The moisture content of the raw material entering the mill is

less than 7%, the moisture content of the final product is 0.5%,

and the fineness of the final product is r80um = 12% - 18%.

Grinding particle size refers to the particle size with 95%

qualified rate.

2. The water content of raw coal is less than or equal to 15%, the

water content of finished product is 1.0%, and the fineness of

finished product is r80um = 10% - 15%.

3. The moisture content of the slag entering the mill is ≤ 20%, the

particle size is ≤ 10 mm, and the moisture content of the finished

product is 0.5%. The fineness of the finished product is

3800cm2-4000cm2.

4. The moisture content of high calcium limestone in the plant is ≤

30%, the moisture content of product is ≤ 0.5%, and the fineness of

final product is r45um = 5% - 20%.

5. The above data description is for reference only.

Features:

1.Large application range,simple structure and convenient maintenance.

2.Large capacity and continuous work are very obvious.

3.The installation and adjustment are very convenient and easy to operate.

Company introduction

Hebei Jinma Mine Machinery Group Co., Ltd. is a professional

manufacturer of "Jinma" metallurgical, mine, construction material

and environmental equipment assemblies. Founded in 1971 and

reorganized into a joint stock enterprise in 1997, the company

consists of Tangshan Mine Machinery Plant, Tangshan Jinma

Construction Material Machinery Co., Ltd., Zunhua Jinma

Environmental Equipment Co., Ltd. and Zunhua Jinma Mining Co., Ltd.

The company covers 50 plus mu of land, with total assets of RMB90

million, some 600 employees including 96 engineering professionals

and a variety of processing and testing devices, including

large-size processing devices like 10t electric arc furnaces,

vacuum casting tools, 8m, 5m and 4m vertical lathes, 8m, 5m and

3.15m hobbing machines, 6m planing machines, fine boring machines

and medium-frequency quenching tools, and automatic welding,

ultrasonic weld testers, W15-23 material testers and time-dependent

vibrators totaling over 300 pieces of equipment.

FAQ to save your precious time!

Q1: Hi, are you a mining machinery manufacturer?

Answer: Yes, we are a professional manufacturer of mining machine.

Our company welcomes customers to visit our factory at any time.

Q2: How long is the warranty period of your equipment? Does your

company provide spare parts?

Answer: The warranty period of our machine is one year. For those

wearing parts, we guarantee to provide high-quality parts for a

long time.

Q3: How long does it take to deliver?

Answer: Production usually starts after receiving the advance

payment. Small machine is guaranteed to be delivered within one

month. Large-scale machine is guaranteed to be delivered within 2-3

months.