Add to Cart

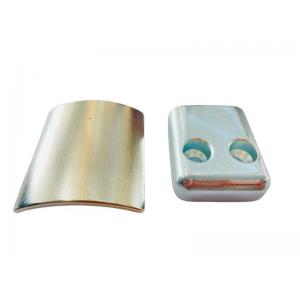

Custom Permanent Neodymium Magnet Ring High Temperature Precision Ferrite Arc

Grade:N35-N52 (M.H.SH.UH.EH.AH)/

NdFeB,N35-N52,35M-50M,33H-48H,33SH-45SH,30UH-40UH,28EH-38EH,30AH-33AH

Shape: Disc, Block, Ring, Arc and so on, Customized, All sizes are ok

Tolerance: ±0.1, 0.01mm-0.1mm

Size: F20*10*2 D12 x 2 Customized Magnet Size

Coating: Ni-Cu--Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr, Neodymium N52 Magnet

Processing Service: Bending, Welding, Cutting, Punching, Moulding

Application: Industrial Magnet, Speaker, Door holder, Motor and rotor

Packing: Standard sea or air packing,such as carton,iron box,wooden box,etc.

Testing: Guass Meter, Fluxmeter,SST, etc

Working Temperature: 80 degree celcius/80-220 degree centigrade

High quality strong sintered N52 neodymium magnets for generator

Neodymium magnets are the strongest permanent. Rare-Earth magnets

commercially available today with magnetic properties that far

exceed other permanent magnet materials.

Their high magnetic strength, resistance to demagnetization, low

cost and versatility

make them the ideal choice for applications ranging from industrial

and technical use to personal projects.

| Tolerance | +/- 0.05mm | |

| Magnetism direction | Thickness, Axial(Other Magnetism direction Contact us) | |

| Coating | Nickel-plated (Ni-Cu-Ni-Au),Zn,Expoy,Sliver,others | |

| Leading Time | 8-25 days | |

| Sample | Avaliable | |

Neodymium( NdFeB )magnets are the type of rare earth magnet

commercially available and are manufactured in a wide range of

shapes,sizes and grades. Neodymium magnets are all graded by the

material they are made of. As a very general rule, the higher the

grade (the number

following the 'N'), the stronger the magnet. The highest grade of

neodymium magnet currently available is N52. Any letter

following the grade refers to the temperature rating of the magnet.

If there are no letters following the grade, then the magnet

is standard temperature neodymium. The temperature ratings are

standard (no designation) - M - H - SH - UH - EH.

Platings/Coatings

Neodymium magnets are a composition of mostly Neodymium, Iron and

Boron. If left exposed to the elements, the iron in the magnet

will rust. To protect the magnet from corrosion and to strengthen

the brittle magnet material, it is usually preferable for the

magnet to be coated. There are a variety of options for coatings,

but nickel is the most common and usually preferred. Our nickel

plated magnets are actually triple plated with layers of nickel,

copper, and nickel again. This triple coating makes our magnets

much more durable than the more common single nickel plated

magnets. Some other options for coating are zinc, tin, copper,

epoxy,

silver and gold. Our gold plated magnets are actually quadruple

plated with nickel, copper, nickel and a top coating of gold.

Application

1.Life consumption: clothing, bag, leather case, cup, glove,

jewelry, pillow, fish tank, photo frame, watch;

2.Electronic product: keyboard, display, smart bracelet, computer,

mobile phone, sensor, GPS locator,Bluetooth, camera, audio, LED;

3.Home-based: Lock, table, chair, cupboard, bed, curtain, window,

knife, lighting, hook, ceiling;

4.Mechanical equipment & automation: motor, unmanned aerial

vehicles, elevators, security monitoring, dishwashers, magnetic

cranes, magnetic filter.

Common direction of magnetization

1> Disc, cylinder and Ring shape magnet can be magnetized

Axially or Diametrically.

2> Rectangle shape magnets can be magnetized through Thickness,

Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through

Width or Thickness.

FAQ

Q:Are you manufactory or trade company.