Add to Cart

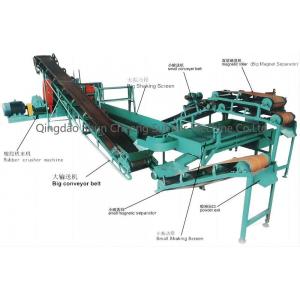

Semi-Auto Waste Tyre Reycling Production Line / Waste Tire Recycling Machine

| Technical parameter Type | XKP-400 | XKP-450 | XKP-560 |

| Front roll diameter(mm) | 400 | 450 | 560 |

| Rear roll diameter(mm) | 400(Groove roller) | 450(Groove roller) | 510(Groove roller) |

| Working length of rolls(mm) | 600 | 650 | 800 |

| Front roll surface speed(m/min) | 17.32 | 23.2 | 25.56 |

| Friction ratio | 1: 1.38 | 1: 1.38 | 1: 1.30 |

| Max. nip(mm) | 8 | 8 | 15 |

| Motor power (kw) | 45 | 55 | 75 |

| dimension(L× W× H)(mm) | 3950× 1800× 1780 | 4770× 1846× 1835 | 5064× 2284× 1978 |

FAQ

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very

beginning to the end of production. Every machine will be fully

assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand

components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How

long time will it take?

Yes, we can supply overseas service and technical support but

customer needs to pay for the cost of the installation. Small

machine usually takes within 2~3 days. Big production line usually

takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed

and confirmed in the order. The core of our company culture is

innovation,quality,integrity and efficiency. Also we have had many

good cooperation with world famous rubber production manufacturers.

If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name

of airport is Qingdao liuting airport. We will pick up you at the

airport.

Before leaving factory, this plate vulcanizing press needs to pass

24 hours' pressure test, pressure maintaining to test the bearing

of the hydro-cylinder and piston stroke and guarantee no oil

leakage and seeping to avoid unnecessary quality problems.

We can design and manufacture all kinds of non-standard plate

vulcanizing press according to the customers' definite

requirements.

♦ Our engineers can design target machines for customers and send

them the drawing to confirm. We are always on the side of saving

your cost.

♦ In the process of production, we will take photos and send to

customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of

lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation

drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your

workers to operate the machine.