Add to Cart

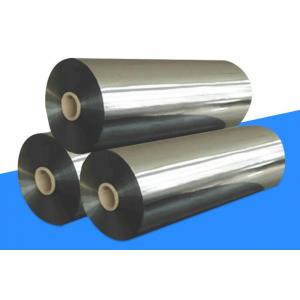

25um20umcpp aluminized film cpp vacuum aluminized film industrial CPP flexible packaging film

Compared with aluminum foil composite materials, aluminized film has the following characteristics:

(1) The amount of aluminum used is greatly reduced, energy and

materials are saved, and costs are reduced. The thickness of the

composite aluminum foil is mostly

7~gpm, while the thickness of the aluminum layer of the aluminized

film is about 0.05n, its aluminum consumption is about 1/140~1/180

of aluminum foil, and the production speed can be as high as

450m/min.

(2) It has excellent folding resistance and good toughness, rarely

pinholes and cracks, no warping and cracking, so the barrier to

gas, water vapor, odor, light, etc. is improved.

(3) It has excellent metallic luster, and the light reflectivity

can reach 97%; and it can form a color film through paint

treatment, and its decoration effect is inferior to that of

aluminum foil.

(4) A shielded type can be used for partial aluminum plating to

obtain any pattern or transparent window to see the contents.

(5) The aluminum-plated layer has good electrical conductivity and

can eliminate electrostatic effects; its sealing performance is

good, especially when packaging powdered products, it will not

pollute the sealing part and ensure the sealing performance of the

package.

(6) Good adaptability to post-processing such as printing and

compounding.

Product Application:

1. For candy wrapping.

2. Packaging food,

3. For decoration, for wrapping flowers, gifts, etc.

4. Used as emergency blanket, it can retains 80% percent of your

radiant body heat

5. For decoration, for wrapping flowers, gifts.

Our factory specializes in selling PET aluminized film, color film, transparent film, polyester color film, and undertakes external processing of PET, OPP, PVC and other film materials. We are based on honesty, professionalism, high quality and low price. We insist on customer-oriented, take consumer satisfaction as the highest criterion, continuously improve the quality of service, and deliver goods for you on time. Products are widely used in packaging, printing, frosting, laminating, etc.

Specification

Testing Items | Technical Request | Result | Conclusion | ||

Physical properties | Tensile strength | MD | ≥170 MPa | 202MPa | Passed |

TD | ≥170 MPa | 276 MPa | Passed | ||

Elongation at Break | MD | ≥80 % | 84 % | Passed | |

TD | ≥80 % | 138 % | Passed | ||

Wetting tension | ≥40 mN/m | 52 mN/m | Passed | ||

Adhesive force | ≤10 % | 0% | Passed | ||

Thickness of Aluminized layer Ω/口 | ≤ 2.5 | 1.65/380Å | Passed | ||

Evenness of Aluminized layer,% f | 15 % | 8 % | Passed | ||

Heat-sealing Strength | / | / | / | ||

Hot-shrinkage rate (MD/TD) | ≤3.0% / ≤2.0% | 1.1% / 0.4% | Passed | ||

friction coefficient(static/dynamic) | ≤0.6/0.6 | 0.56/0.55 | Passed | ||

Oxygen Permeation cm³/ (㎡.24h.0.1Mpa) | / | / | / | ||

Vapor Permeation g/ ( ㎡24h) | ≤2.5 | / | / | ||

Conclusion | Passed | ||||

Remark | The test result is for this batch only. | ||||

Product Show