Product Details

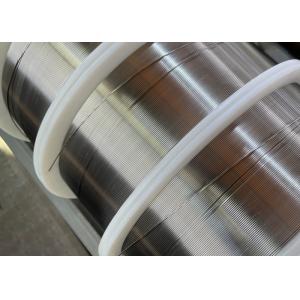

ERNiCrMo-13 Nickel-Chromium-Molybdenum Alloy UNS N06059 1.2mm Mig

Welding Wire Rod For Welder

- Nickel Based Welding Wire

AWS 5.14 MIG / TIG Nickel Alloy Welding Wire /Rod ERNiCrMo-3

ERNiCrMo-4 ERNiCr-3 ERNi-1 ErNiCrMo-13

Nickel based Inconel 625 welding wire ENiCrMo-3 has good resistance

to corrosion and high temperature,and has high strength and good

fabricability.it is widely used in petrochemical, metallurgy,

atomic energy, ocean development, aviation, aerospace and other

industries.

Welding series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1,

ER70S-6.

Standard: Conforms to Certification AWS A5.14 ASME SFA A5.14

Size: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM /

5.0MM

Form: MIG(15kgs/spool), TIG(5kgs/box),Strip

Nickel welding wire Nickel welding wire Nickel welding wire Nickel

welding wire Nickel welding wire

Chemical Properties of Nickel welding wire ERNiCrMo-13

| C | Mn | Si | Fe | S | P | Cu | Al | Co | Ni | Cr | Mo | | max 0.01 | max 0.5 | max 0.5 | max 1.5 | max 0.01 | max 0.015 | max 0.5 | 0.1-0.4 | max 0.3 | Balance | 22-24 | 15.0-16.5 |

| |

Nickel Welding Wire Nickel Welding Wire Nickel Welding Wire Nickel Welding Wire

| MIG | (15kg/spool), | Size |

| | 0.8 1.2 2.4 3.2mm |

| TIG | (5kg/box),Strip |

Company Profile

Changzhou DLX Alloy Co., Ltd. was established in 2016 and has

passed ISO9001 international quality management system

certification and SGS certification. Our factory is becoming a

high-tech enterprise specializing in the research and production of

special alloy materials. The production process includes melting,

drawing, heat treatment, precision machining, and testing.

Main categories: electric heating wire, nickel welding wire,

thermocouple wire, corrosion-resistant alloy, thermal spraying

alloy