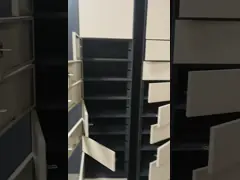

Roller Shutter Door Vertical 1.8m High Lockable Filing Cabinets Officeworks

Add to Cart

Roller Shutter Door Iron Steel Lockable Filing Cabinets Vertical

Application of Steel Lockable Filing Cabinets

Primary School,Elementary School,Middle School,High School & University.

Steel Lockable Filing Cabinets Description

| Product Name | Roller Shutter Door Iron Steel Lockable Filing Cabinets Vertical |

| Size | 850W*390D*1850H (mm) Customer Size Accepted |

| Body Materail | Made of 0.6 thick cold rolled steel ,with chemical-resist powder coating available in many colors. 0.7mm/0.8mm/0.9mm/1.0mm/1.1mm/1.2mm thickness of steel sheet available |

| Painting Process | washing--pickling--phosphating--acid wasing---pre-bake--powder paited--solidify. |

| Craft Process | Raw Material--CNC Cutting--Punching--Bending--Spot Welding--Coating--Package--Shipment |

| Handles | Integrated with door and drawer/Plastic/Aluminum alloy |

| Loading Qty | 20GP:400pcs, 40GP:405pcs, 40HQ:490pcs |

| Term Of Payment | L/C or 30% T/T deposit before production, 70%T/T before loading the container. |

1.The surface is sprayed, baked and cured The surface is made of fine powder coating, after electrostatic spraying, baked and cured at high temperature. Wear - resistant, scratch - resistant, rust - proof, splash - proof, durable bright color.

The 2000W CNC optical fiber laser cutting machine imported from Germany is used for fast speed and accurate data.

3.High quality slides

Free and smooth push and pull, good load bearing force, small slide resistance, long service life, drawer smooth.

4.Large space for storage.

The middle partition can be adjusted freely to avoid congestion and clutter, and the space can be organized in a more orderly way to meet the daily needs of office storage.

5.Cyber lock or WT lock

1.Reinforced laminate:

Under the high-quality cold-rolled steel laminate, cold-rolled steel reinforcement is adopted to enhance its bearing capacity and make the laminate not easy to be deformed;

2.Thickened baffle plate:

The baffle plate is made of cold-rolled steel plate, which

increases the material thickness, has strong bearing force,

pressure resistance and is not easy to be deformed.

3.Cabinet materials.

The cabinet is made of high quality thickened cold-rolled steel plate, which is welded and assembled with carbon dioxide gas protection after cold processing. The structure of the cabinet is firm and firm.The surface of the box after rust removal, oil removal, grinding, phosphating treatment after spraying.

4.Phosphorus - free electrostatic spraying.

The surface is smooth, the color is bright, the adhesion ability is strong, not easy to drop the paint, the coating micro hole is small, the anticorrosion performance is high.

5.The structure is smooth and precise.

Precision design, uniform size, precise and smooth stitching, firm structure, stronger load bearing.

6.Cabinet materials.

The cabinet is made of high quality thickened cold-rolled steel plate, which is welded and assembled with carbon dioxide gas protection after cold processing. The structure of the cabinet is firm and firm.The surface of the box after rust removal, oil removal, grinding, phosphating treatment after spraying.

Inspection System: Checking quality before packing.

Documents Cabinet Main Manufacturing process

2. Stamping: use the punch machine to punch out the corner edge, handle and other positions that need to be reserved.

3. Bending: use the bending machine to fold the inside and outside edges.

4. Welding: reinforce with spot welding machine.

5.Polished: the surface of the solder joint polished, is smooth surface without burr.

6. Pickling and phosphating: put the welded file cabinet down the chemical tank for oil removal and rust removal.

7. Spray molding: semi-finished products enter the spray table and are sprayed with static electricity.

8. Assembly: assemble door, handle, key and other accessories.

9.Inspection: inspection by inspectors

10.Finished product: wrapped in paper.