Add to Cart

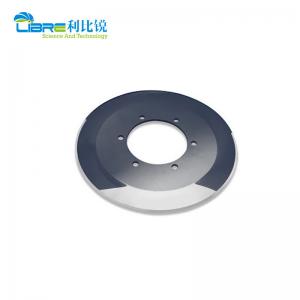

Corrugated Paper Manufacturing Machinery Corrugated Paper Knives

Tungsten carbide slitting knife for corrugated machine are made by

high quality virgin tungsten carbide

powder and cobalt powder with powder metallurgy method. Compared

with the traditional steel blade,

Our tungsten carbide blades have higher hardness (HRA 89 to 93) and

wear resistance (3500 to 4000 Mpa).

In the past 20 years, our knives are widely used in BHS, Fosber,

Marquip, Agnati, Mitshubishi, TCY, Justu,

K&H,...Machines. Our high-quality products and factory prices

have won the vast domestic and foreign

markets for our distributors.

Our knives can help you with the bellow THREE ASPECTS:

Corrugated Paper Knives Common Sizes:

| Model | OD | ID | Thickness | Number of holes | Hole dia |

| Agnati | 220 | 115 | 1.0 | 3 | 9.0 |

| Agnati | 240 | 115 | 1.0 | 3 | 9.0 |

| Agnati | 240 | 115 | 2.0 | 3 | 9.0 |

| BHS | 240 | 32 | 1.2 | 2 | 8.5 |

| Fosber | 230 | 110 | 1.1 | 6 | 9.0 |

| Fosber | 230 | 135 | 1.1 | 6 | 9.0 |

| Fosber | 291 | 203 | 1.1 | 6 | 8.5 |

| Isowa | 260 | 140 | 1.1 | 6 | 9.5 |

| Marquip | 260 | 168.3 | 1.2/1.3 | 8 | 10.5 |

| Mitsubishi | 280 | 202 | 1.4 | 6 | 7.6 |

| Mitsubishi | 280 | 160 | 1.1 | 6 | 7.6 |

| Peters | 250 | 150 | 0.8 | ||

| Peters | 250 | 150 | 1.2 | ||

| TCY | 300 | 112 | 1.2-1.5 | 6 | 12.0 |

| Justu | 200 | 122 | 1.2/1.3 | ||

| Kaituo | 230 | 110 | 1.3/1.4 | ||

| Justo | 260 | 158 | 1.4/1.5 | 8 | 11.0 |

| Oranda | 265 | 112 | 1.4 |

Carbide Slitter Knives Display:

Application of Cardboard Cutting Blades:

F.A.Q.

1. The short working life time of corrugated board knives.

Is the grain size of the grinding wheel proper?

Too coarse grain size of grinding wheel: make a short working life

time of knives

2. The edges of corrugated boards cut by knives with burr and dent

Please check the cutting edge of your blade. Is the cutting edge

keen enough

the corrugated board is too wet ?

3. Break of knife

1) Improper assembly will cause the quick break of blades. Any

improper touch of the

blade is strictly prohibited during the working

2) Unstable swing grinding wheels break the knives, please check

the bearing of

grinding wheels.

3) Improper touch or strike with other hard things

4) Accident collision of knives.

4. Chips on the cutting edge after the grinding

1) Unstable swing grinding wheels may cause this problem ,even

break the knives

2) The strike of hard things may cause the chips on the cutting

edge

5.The edge of corrugated board is not straight

Unmatched strength of knives for the corrugated board with high

density