Add to Cart

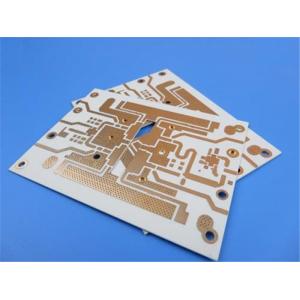

We are excited to introduce our latest shipment, an exceptional printed circuit board (PCB) meticulously supplied for meet the needs of modern electronic applications. Crafted with precision and reliability in mind, this PCB offers outstanding performance and top-notch quality. Let's delve into the key details of this remarkable PCB.

PCB Material and Stackup:

This PCB is built with RO4003C hydrocarbon ceramic laminates,

renowned for their superior electrical properties and stability. It

proceeding with a lead-free process, aligning with environmental

standards and regulations. The PCB is designed to operate

flawlessly within a temperature range of -40℃ to +85℃, making it

suitable for a wide range of environmental conditions.

Construction Details:

The PCB features a 2-layer rigid design with a finished copper

thickness of 35um, ensuring excellent electrical conductivity. The

RO4003C dielectric layer provides a thickness of 32mil, ensuring

reliable insulation and exceptional signal integrity. The second

layer also boasts a finished copper thickness of 35um to maintain

consistent performance.

The PCB's dimensions measure 139mm x 100mm (6PCS), and we ensure high precision with an accuracy level of +/- 0.15mm. You can achieve intricate and precise circuitry with a minimum trace/space of 4/4 mils. The minimum hole size of 0.5mm allows compatibility with a wide range of components.There are no blind or buried vias.

To ensure durability and stability, its finished board thickness of 0.9mm. The PCB features a 1 oz (1.4 mils) copper weight across all layers to optimize conductivity. For reliable electrical connections, we employ 1 mil via plating thickness. The surface finish is Electroless Nickel Immersion Gold (ENIG), which offers exceptional solderability and corrosion resistance.

The PCB do not require top and bottom silkscreen and solder mask, resulting in a clean and minimalistic appearance. Silkscreen is absent on solder pads to ensure precise component placement. To guarantee functionality and reliability, the PCBs are 100% electrical test. Additionally, the 0.5mm vias are filled with resin and capped according to IPC-4761 Type VII standards to enhance structural integrity.

PCB Statistics:

The PCB accommodates 97 components and provides a total of 130 pads

for secure component attachment. It includes 49 thru-hole pads and

81 top SMT pads, offering versatile component mounting options. The

configuration does not include bottom SMT pads. With 151 vias,

seamless electrical connections are achieved, supporting 17 unique

nets for efficient signal routing.

Artwork Format and Accepted Standard:

We accept the Gerber RS-274-X format, ensuring compatibility with

industry-standard PCB design software. PCB processes adhere to the

IPC-Class-2 standard, guaranteeing high-quality production and

reliability.

Service Area:

Our services are available worldwide, allowing customers from any

corner of the globe to access our exceptional products and support.

Contact Information:

For technical inquiries or further details, please reach out to Ivy

at sales10@bichengpcb.com. We are dedicated to providing

exceptional customer service and technical support tailored to your

specific requirements.

| RO4003C Typical Value | |||||

| Property | RO4003C | Direction | Units | Condition | Test Method |

| Dielectric Constant,εProcess | 3.38±0.05 | Z | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline | |

| Dielectric Constant,εDesign | 3.55 | Z | 8 to 40 GHz | Differential Phase Length Method | |

| Dissipation Factortan,δ | 0.0027 0.0021 | Z | 10 GHz/23℃ 2.5 GHz/23℃ | IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of ε | +40 | Z | ppm/℃ | -50℃to 150℃ | IPC-TM-650 2.5.5.5 |

| Volume Resistivity | 1.7 x 1010 | MΩ.cm | COND A | IPC-TM-650 2.5.17.1 | |

| Surface Resistivity | 4.2 x 109 | MΩ | COND A | IPC-TM-650 2.5.17.1 | |

| Electrical Strength | 31.2(780) | Z | Kv/mm(v/mil) | 0.51mm(0.020") | IPC-TM-650 2.5.6.2 |

| Tensile Modulus | 19,650(2,850) 19,450(2,821) | X Y | MPa(ksi) | RT | ASTM D 638 |

| Tensile Strength | 139(20.2) 100(14.5) | X Y | MPa(ksi) | RT | ASTM D 638 |

| Flexural Strength | 276 (40) | MPa (kpsi) | IPC-TM-650 2.4.4 | ||

| Dimensional Stability | <0.3 | X,Y | mm/m (mil/inch) | after etch+E2/150℃ | IPC-TM-650 2.4.39A |

| Coefficient of Thermal Expansion | 11 14 46 | X Y Z | ppm/℃ | -55℃to288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | ℃ TMA | A | IPC-TM-650 2.4.24.3 | |

| Td | 425 | ℃ TGA | ASTM D 3850 | ||

| Thermal Conductivity | 0.71 | W/M/oK | 80℃ | ASTM C518 | |

| Moisture Absorption | 0.06 | % | 48hrs immersion 0.060" sample Temperature 50℃ | ASTM D 570 | |

| Density | 1.79 | gm/cm3 | 23℃ | ASTM D 792 | |

| Copper Peel Stength | 1.05 (6.0) | N/mm (pli) | after solder float 1 oz. EDC Foil | IPC-TM-650 2.4.8 | |

| Flammability | N/A | UL 94 | |||

| Lead-free Process Compatible | Yes | ||||

Revolutionizing High-Performance PCBs with RO4003C Hydrocarbon Ceramic Laminates

Introduction:

In the rapidly evolving landscape of electronic applications, the

demand for high-performance printed circuit boards (PCBs) continues

to soar. RO4003C hydrocarbon ceramic laminates have emerged as a

game-changing PCB material, renowned for its exceptional quality

and outstanding performance. In this article, we will delve deep

into the features, benefits, and applications of RO4003C, shedding

light on its potential to revolutionize the world of PCBs.

Advantages and Features of RO4003C for High-Performance PCBs:

RO4003C hydrocarbon ceramic laminates offer a host of advantages

that make them an ideal choice for high-performance PCBs. With a

dielectric constant of 3.38±0.05, RO4003C ensures reliable

electrical properties and signal integrity. Its low dissipation

factor (tan, δ) of 0.0027 at 10 GHz/23℃ and 0.0021 at 2.5 GHz/23℃

further enhances its performance in high-frequency applications.

Thermal Considerations: Coefficient of Thermal Expansion and

Dimensional Stability:

RO4003C exhibits excellent thermal stability with a thermal

coefficient of ε of +40 ppm/℃ in the range of -50℃ to 150℃. This

ensures that the PCB maintains its structural integrity and

electrical properties across a wide temperature range.

Additionally, its dimensional stability of less than 0.3 mm/m

(mil/inch) after etch+E2/150℃ guarantees reliable performance even

in demanding thermal environments.

Electrical Properties of RO4003C: Dielectric Constant and

Dissipation Factor:

The dielectric constant (ε) of RO4003C, measured using the

IPC-TM-650 2.5.5.5 Clamped Stripline process, is 3.38±0.05. This

low dielectric constant ensures minimal signal loss and excellent

impedance control, making RO4003C suitable for high-speed digital

and RF applications. The dissipation factor (tan, δ) of RO4003C,

measured at 10 GHz/23℃ and 2.5 GHz/23℃, is 0.0027 and 0.0021,

respectively. These low values indicate low signal attenuation and

efficient power transmission.

Ensuring Signal Integrity: Electrical Strength and Surface

Resistivity of RO4003C:

RO4003C boasts impressive electrical strength, with a value of 31.2

(780) Kv/mm (v/mil) at a thickness of 0.51mm (0.020"). This high

electrical strength enables RO4003C to withstand high voltages and

prevent electrical breakdown. Additionally, the surface resistivity

of RO4003C is 4.2 x 10^9 MΩ, ensuring effective insulation and

minimizing leakage currents.

Mechanical Strength: Tensile Modulus and Strength Analysis of RO4003C:

RO4003C exhibits remarkable mechanical strength, with a tensile modulus of 19,650 MPa (2,850 ksi) in the X direction and 19,450 MPa (2,821 ksi) in the Y direction. Its tensile strength is 139 MPa (20.2 ksi) in the X direction and 100 MPa (14.5 ksi) in the Y direction. These properties make RO4003C highly resistant to deformation and ensure the structural integrity of PCBs even under demanding conditions.

Applications of RO4003C in Various Industries:

The versatility of RO4003C opens up a wide range of applications

across various industries. Its exceptional electrical properties,

combined with high thermal stability, make it an excellent choice

for telecommunications, aerospace, automotive, and wireless

communication systems. RO4003C can be used in high-frequency PCBs,

microwave circuits, power amplifiers, antennas, and radar systems,

among others.

Sustainability and Lead-Free Compatibility of RO4003C:

As the industry moves towards more sustainable practices, RO4003C

stands out as an environmentally friendly choice. It is compatible

with lead-free processes, ensuring compliance with regulations and

reducing the environmental impact of PCB manufacturing. By choosing

RO4003C, companies can contribute to a greener future and meet the

demands of eco-conscious customers.

High-Frequency Performance: RO4003C for GHz Range Applications:

RO4003C's exceptional electrical properties and low loss tangent

make it particularly suitable for high-frequency applications in

the GHz range. With a dielectric constant of 3.55 (measured using

the Differential Phase Length Method), RO4003C provides precise

impedance control and minimizes signal distortions. It enables the

design and manufacturing of high-performance RF and microwave

circuits that operate in the GHz frequency range.

Thermal Management with RO4003C: Thermal Conductivity and Cooling

Efficiency:

Efficient thermal management is crucial for electronicdevices,

especially those operating at high power levels. RO4003C excels in

this aspect with its thermal conductivity of 0.71 W/M/oK at 80℃.

This high thermal conductivity facilitates effective heat

dissipation, reducing the risk of component overheating and

ensuring reliable performance. The superior cooling efficiency of

RO4003C makes it an excellent choice for power amplifiers,

high-power RF modules, and other heat-sensitive applications.

Conclusion:

RO4003C hydrocarbon ceramic laminates offer a myriad of features

and benefits that make them a top choice for high-performance PCBs.

With exceptional electrical properties, outstanding thermal

stability, and impressive mechanical strength, RO4003C enables the

design and manufacturing of reliable and efficient electronic

systems. Its compatibility with lead-free processes and

sustainability aspects further enhance its appeal. Whether in

telecommunications, aerospace, automotive, or other industries,

RO4003C empowers engineers and designers to push the boundaries of

innovation and achieve unprecedented performance in their PCB

applications.