Product Details

Fabrication Integrity – Bubble Test ISO 2942-2004

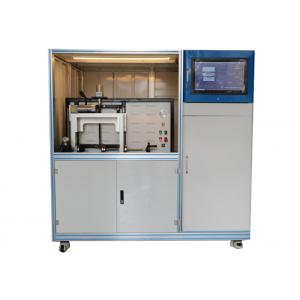

Product overview:

The Fabrication Integrity and First Bubble Point Test Rig for Filter Element is used to verify the fabrication integrity

of a filter element (by checking the absence of bubbles) or to

permit the localization of the largest pore of the filter element

by determining the first bubble point.

Verification of the fabrication integrity defines the acceptability

of the filter elements further use or testing. Auto Parts Test Equipment

The first bubble point is established through continuation of the

fabrication integrity test. It is under no circumstances a

functional characteristic of a filter element; in particular, it

can not be used for extrapolation to the concepts of filtration

rating, efficiency or retention capacity and should be used for

information only.

Test Principle:

Install the tested filter element in the test container clean

designated test liquid manually. The filter element is submerged in

the test liquid, the filter element keeps rotating automatically,

and the set air pressure is automatically increased during the

test. Manually record the corresponding pressure value and bubbling

point location, and input the computer to automatically generate a

test report.

Standard:

The fabrication integrity and first bubble point test rig for

filter element meet the standard of ISO 2942-2004, GB/T

14041.1-2007.

Test object:

Filter element used in hydraulic fluid power systems. Auto Parts Test Equipment

Parameters:

| Air compressor | With filter and pressure regulator, adjustable up to 200 mbar |

| Gas pressure sensor | With an accuracy of ± 5% of the reading |

| Liquid temperature sensor | With an accuracy of ± 5 °C Auto Parts Test Equipment |

Company Profile

Guangzhou Hejin Automation Control Technology Co., Ltd. is a modern

enterprise specialized in R & D, manufacturing and sales of

technology intensive industrial equipment. Its main products

include laboratory testing equipment and production line detection

system, which are widely applied to refrigeration, automotive,

electric power industries, military, home appliances and other

industries.

The company is led by Mr. Li Jianhe, an expert with profound

knowledge in vacuum and automatic testing equipment. The company

has its own core technology and a number of invention and utility

model patents. Relying on a high-level talent team, the company

adopts a new production mode focusing on development and design,

assembly and debugging and after-sales service, and launches

products suitable for its use and technical requirements according

to different situations of customers. Since its establishment, the

company has launched various types of special equipment to the

market. While meeting the domestic market demand, the equipment is

also exported to the Americas, Europe, Asia and Africa and other

countries and regions. The pursuit of excellence and respect is the

business philosophy and the highest guiding principle of the

company's operation and management.

Our business goal is to rely on our technology to provide customers

with excellent products and services. We will promote core

competitiveness, create high performance, and build into the

world's top brand in the field of automation and control.

HeJin Product Series:

Auto Parts Test Equipment

Leak Testing Equipment

IP Test Equipment

Automatic flame Brazing Machine

Flammability Testing Equipment

Impact Testing Machine

Plug Socket Test Equipment

Test Finger Probe

Household Appliance Test Equipment

Appliance Performance Test Lab