Product Details

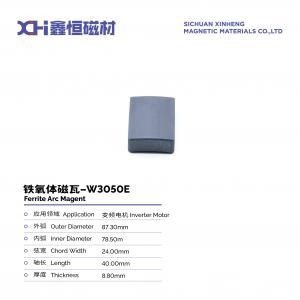

Wet Pressed Ferrite Magnets For High Density Inverter Motors W3050E

Introduction Of Inverter Motor:

An inverter motor, also known as a variable frequency drive (VFD)

motor, operates based on the principles of variable frequency

control and motor speed regulation. It is commonly used in various

applications where precise speed control and energy efficiency are

required.

Variable Frequency Control: An inverter motor operates by adjusting

the frequency of the electrical power supplied to the motor. Unlike

traditional motors that operate at a fixed frequency, inverter

motors allow for flexible and adjustable frequency control. By

varying the frequency, the motor's rotational speed can be

precisely regulated.

Power Conversion: Inverter motors utilize power electronics and

control circuits to convert the incoming AC power into DC power.

The DC power is then inverted back into AC power at the desired

frequency and voltage levels. This conversion process allows for

the generation of variable-frequency power that drives the motor.

What's the feature of ceramic strontium ferrite magnet made by wet

compression molding?

Composition - Contain strontium ferrite (SrFe12O19) as the primary

magnetic material. Strontium ferrite has good magnetic properties

and is inexpensive to produce.

Density - Have a high relative density of around 95% or more after

sintering. This gives good mechanical strength.

An-isotropy - Exhibit strong magnetocrystalline an-isotropy due to

their hexagonal crystal structure. This results in a preferred

direction of magnetization along one axis.

Particle shape - The strontium ferrite powder used typically has a

hexagonal platelet morphology which helps promote magnetic

an-isotropy during molding and sintering.

Molding method - The powder is mixed with a liquid binder and

compression molded into a dense green compact using high pressures.

This orients the an-isotropic particles.

Firing process - The compact is then sintered at high temperature

to develop density while preserving the induced magnetic anisotropy

orientation from molding.

Remanence - Have a maximum magnetic flux density or remanence along

the axis of anisotropy, but little/no remanence perpendicular to

it.

Coercivity - Usually have medium to high coercivity depending on

additives, density, and anisotropy level achieved.

What's the key advantages of ceramic strontium ferrite magnets made

by wet compression molding?

Low cost - Strontium ferrite is inexpensive and the wet molding

process is relatively simple. This makes them cheaper than

rare-earth magnets.

High magnetic property-Even without heavy rare earth element

additions, strontium ferrite magnets can achieve coercivities of

700-1000 kA/m, making them suitable for many applications.

Dimensional consistency - The compression molding process allows

for close dimensional tolerances and uniform magnet shapes to be

produced consistently.

Temperature stability - Strontium ferrite magnets have high Curie

temperatures, typically around 450-470°C. They maintain good

magnetic properties over a wide operating temperature range.

Resistance to corrosion - Being fully dense ceramic materials, they

are not prone to corrosion like bonded magnets containing

additives.

Mass production capability - The molding process is amenable to

automated high-volume manufacturing of complex magnet geometries.

PHYSICAL PROPERTIES OF SINTERED FERRITE MAGNETS

| Units | Sintered Ferrite (Ceramic) |

| Curie Temperature | ºC | 450 |

| Maximum Operating Temperature | ºC | 350 |

| Hardness | Hv | >530 |

| Density | g/cm3 | 4.8 – 5.0 |

| Relative recoil permeability | μrec | 1.05-1.1 |

| Temperature Coefficient Br | %/ºC | -0.18 |

| Temperature Coefficient iHc | %/ºC | 0.11-0.40 |

| Anti-Bending Strength | N/m2 | (0.5-0.9)×108 |

| Anti-Compressive Strength | N/m2 | ≥6.9×108 |

| Anti-Tensile Strength | N/m2 | (0.2-0.5)×108 |

| Specific Heat | J/kg·K | 600-900 |

| Resistivity | Q.cm | >104 |

What's the application of Xinheng's permanent ferrite magnets?

Xinheng mainly manufactures the following types of ceramic arc

segment magnets:

- Automotive motor magnet including automobile starter motor magnet,

automobile wiper motor magnet, automobile rolling window motor

magnet, automobile heating and cooling fan motor magnet, automobile

seat motor magnet, automobile sunroof motor magnet, automobile

powsteering motor magnet, automobile tailgate motor magnet,

automobile oil pump motor magnet, automobile ABS anti-lock motor

magnet, etc.

- Inverter home appliance magnet including inverter washing machine

motor magnet, inverter refrigerator motor magnet, inverter

air-conditioner motor magnet,etc.

- Fan motor magnet including ceiling fan motor magnet, floor fan

magnet, etc.

- Motorcycle motor magnet including motorcycle starter motor magnet,

motorcycle flywheel magneto magnet, etc.

- Electrical tool motor magnet including cutting machine motor

magnet, electric sawing machine motor magnet, lawn mower motor

magnet, gasoline generator magnet, etc.

- Actuator motor magnet including medical bed actuator motor magnet,

TV lifting bracket actuator motor magnet, desk lifting actuator

motor magnet, smart home appliance actuator motor magnet, etc.

How Xinheng fabricates its permanent strontium ferrite magnet?

FERRITE POWDER GRADE OF INVERTER MOTORS MAGNET

Grade | Br(mT) | Hcb(KA/m) | Hcj(KA/m) | (BH)max(KJ/m3) | | mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m3 | MGOe | | Y33 | 410-430 | 4100-4300 | 220-250 | 2760-3140 | 225-255 | 2830-3200 | 31.5-35.0 | 3.9-4.4 | | Y33H | 410-430 | 4100-4300 | 250-270 | 3140-3390 | 250-275 | 3140-3450 | 31.5-35.0 | 3.9-4.4 | | Y33H-2 | 410-430 | 4100-4300 | 285-315 | 3580-3960 | 305-335 | 3830-4200 | 31.8-35.0 | 4.0-4.4 | | Y34 | 420-440 | 4200-4400 | 200-230 | 2510-2890 | 205-235 | 2570-2950 | 32.5-36.0 | 4.1-4.4 | | Y35 | 430-450 | 4300-4500 | 215-239 | 2700-3000 | 217-241 | 2730-3030 | 33.1-38.2 | 4.1-4.8 | | Y36 | 430-450 | 4300-4500 | 247-271 | 3100-3400 | 250-274 | 3140-3440 | 35.1-38.3 | 4.1-4.8 | | Y38 | 440-460 | 4400-4600 | 285-305 | 3580-3830 | 294-310 | 3690-3890 | 36.6-40.6 | 4.6-4.8 | | Y40 | 440-460 | 4400-4600 | 330-354 | 4150-4450 | 340-360 | 4270-4520 | 37.6-41.8 | 4.7-5.2 |

|

INVERTER MOTORS MAGNET SPECIFICATION TABLE

| No. | Item | R | r | W | L | h | Grade | Application | | 1 | W118 | 68.1 | 60.7 | 25 | 25 | 7.50 | Y33H | 1KW inverter motor | | 2 | W018F | 72.5 | 60.7 | 27.9 | 35 | 11.80 | Y40 | 2KW inverter motor | | 3 | W005A | 72.5 | 60.5 | 29.5 | 42 | 11.80 | Y33H | 2.3KW inverter motor | | 4 | W050E | 87.3 | 78.5 | 24 | 40 | 8.80 | Y33H | 2.6KW inverter motor | | 5 | W159 | 74.1 | 65.5 | 28.86 | 47 | 8.60 | Y40 | 2.8KW inverter motor | | 6 | W017F | 86.5 | 78.5 | 24.0 | 51 | 7.90 | Y33H-2 | 3KW inverter motor | | 7 | W087 | 86.5 | 78.5 | 24.0 | 64 | 7.80 | Y33H-2 | 5KW inverter motor | | 8 | W138C | 101 | 90.2 | 24.5 | 65 | 10.8 | Y40 | 7KW inverter motor | | 9 | W019B | 112 | 100 | 28.5 | 60 | 11.90 | Y40 | 9KW inverter motor |

|

To know more about Xinheng Magnets

Company Profile

Sichuan Xinheng Magnetic Materials Co., Ltd is located in Mianzhu City, Sichuan Province, which has been known

as " the leader of ancient Shu and the important town of Yizhou "

since ancient times.

The company was founded in May 2008. It was formerly the designated

magnetic material production enterprise of the Ministry of

Electronic Industry in Aba Prefecture, Sichuan Province. After

decades of accumulation in the magnetic materials industry, the

company has developed into a national high-tech enterprise

integrating the design, development, production and sales of

permanent magnet ferrites. Our factory covers an area of 14,000

square meters, has an annual production capacity of 8,000 tons, and

has more than 350 employees.

The company owns China's first independently developed servo fully

automatic wet hydraulic press and China's first double-layer roller

kiln.It has the ability to independently design, develop and

process various types of tools and molds.

The company's main product is sintered ferrite permanent magnet.

The product range covers automobile motors, motorcycle motors,

universal mechanical motors, household appliance motors, household

fan motors, variable inverter motors, water pump motors, etc. The

products are widely used in automobiles and motorcycles, office

equipment, electric tools, household appliances, fitness equipment

and other fields.

The company's products are mainly sold to motor manufacturers in

Europe, America, South Asia, Taiwan, southwest China, East China,

and South China.

The company adheres to the business tenet of "quality assurance,

professional service, and customer satisfaction". Its business

philosophy is to improve the level of operation and management, to

imporove the quality of employees, reduce production costs, and

improve the market competitiveness of enterprises. It adheres to

the development philosophy of putting people first, making

high-quality products with heart, seeking development through

innovation, and building brands with integrity. We are willing to

create a win-win relationship and grow together with our customers!