Add to Cart

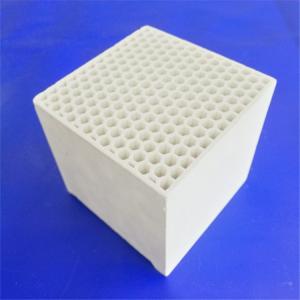

Custom Honeycomb Ceramic Regenerator Ceramic Honeycomb Body

As the main core component of high-temperature air combustion technology (HTAC technology), regenerative burners require honeycomb ceramics as regenerators to have good heat storage characteristics, low resistance characteristics and high temperature resistance characteristics, so as to protect industrial kilns applying HTAC technology The furnace achieves the expected goals of energy saving, environmental protection and increasing output. Therefore, in the production of honeycomb ceramic regenerators, our company strictly carries out the optimization design of raw material formula and process system, with a view to more perfectly match the expected effect of HTAC technology.

The use of honeycomb ceramics is very wide, as follows:

1. Catalyst Carrier

When honeycomb ceramics are used as catalyst carriers, they are

mainly used in automobile exhaust purification, boiler exhaust

denitration (NOx), industrial exhaust deodorization, and removal of

toxic and harmful gases.

The honeycomb ceramic catalyst carrier for automobile exhaust gas

purification is mainly a cordierite honeycomb ceramic carrier

coated with γ-Al2O3.

2. Refractory kiln furniture

The quality of extruded honeycomb ceramic kiln furniture is 60%-75%

lighter than that of traditional kiln furniture. The heat transfer

is rapid, which can achieve rapid firing. When it is used to burn

ferrite or other electronic ceramics, it is beneficial to improve

the performance of the product.

3. Wall flow filter

The porous thin-walled honeycomb ceramics can filter and purify the

carbon particles in the diesel exhaust gas (about 500 ℃).

Material Project | Alumina AL203 | Silicon carbide sic | Silicon nitride sin | Silicon nitride sin | ||||

| Color | Ivory | black | black | Milky white, gray black | ||||

| Content(%) | 99.5 | …… | …… | …… | ||||

| Main features |

|

|

|

| ||||

| The main purpose |

|

|

|

| ||||

| Density | Kg/m³ | 3.9*10 | 3.16*10 | 3.3*10 | 6.0*10 | |||

Mechanical behavior | Vickers hardness | Gpa | 16.0 | 23.0 | 14.0 | 13.2 | 12.7 | |

| Flexural strength | Mpa | 360 | 450 | 1020 | 1000 | 1470 | ||

| Compressive strength | Mpa | 2350 | …… | …… | …… | …… | ||

| Fracture toughness | Mpa | 4 | 2-3 | 7 | 4-5 | 4-5 | ||

Thermal performance | Linear expansion coefficient | 40-400℃ | ×10-5/℃ | 7.2 | 3.7 | 2.8 | 10.5 | 10.8 |

| 40-800℃ | 8.0 | 4.4 | 3.3 | 11.0 | 11.3 | |||

| Thermal conductivity | W/(m·k) | 32 | 200 | 27 | 3 | 3 | ||

| Specific heat | J/(kg·k) | 0.78*10 | 0.67*10 | 0.65*10 | 0.46*10 | 0.46*10 | ||

| Thermal shock resistance (in water) | ℃ | 250 | …… | >800 | 300 | 350 | ||

| Electrical performance | Dielectric strength | V/m | 15*105 | …… | 13*105 | 11*105 | …… | |

| Volume resistance(20℃) | Ω·cm | >1014 | 108 | 1014 | 1013 | …… | ||

| Dielectric constant | …… | 9.6 | …… | 9.9 | 33 | …… | ||

| Loss factor | ×10-4 | 10 | …… | …… | 520 | …… | ||

The characteristics of honeycomb ceramics: environmentally friendly ceramics. Due to their high strength, high temperature resistance, corrosion resistance, and wear resistance, ceramic materials can be widely used in various environmental protection fields, such as automobile exhaust emissions.

Widely used in steel, machinery, building materials, petrochemical, non-ferrous metal smelting and other industries.

The honeycomb ceramics are composed of countless equal holes of various shapes. The large number of holes has reached 120-140 per square centimeter, the density is 0.3-0.6 grams per cubic centimeter, and the water absorption rate is as high as more than 20%.Due to the characteristics of porous thin walls, the geometric surface area of the carrier is greatly increased and the thermal shock resistance is improved. The meshed pores of the products produced are mainly triangular and square, and the triangular triangle has much better bearing capacity and more holes. This is especially important as a catalytic carrier. As the number of holes per unit area increases and the thickness of the carrier wall decreases, the thermal shock resistance of the ceramic carrier increases, as does the temperature of thermal shock failure. Therefore, the honeycomb ceramic must reduce the expansion coefficient and increase the number of holes per unit area. The coefficient of thermal expansion is the main performance index. The current foreign level is α25-800℃≤1.0×10-6℃-1, which has a certain gap with the domestic comparison, but this gap is getting smaller and smaller. The raw materials for the production of honeycomb ceramics are mainly kaolin, talc, aluminum powder, clay, etc., especially the application of diatomaceous earth, zeolite, expansive soil and refractory materials.

In addition to the honeycomb ceramics used for sintering, honeycomb ceramics that are not sintered also appear, which greatly improves the activity of the catalytic performance. Not only the appearance size has evolved from a small spherical ring shape to large-sized columns and square and round shapes. According to different mold design; honeycomb ceramics with different sizes, different shapes and different structures can be made. For example, the molecular sieve catalyst used in the oil refining air adsorption and drying in the petrochemical industry has a size of up to 0.8m and a width of 0.25m, and the number of holes reaches 25 per square centimeter. There have been great changes in raw materials, processes and machinery manufacturing. Especially the production process has been greatly improved. The honeycomb ceramic used as a catalyst requires no cracking during manufacturing and molding, and the organic components must be released cleanly. In addition to the wear resistance, it also requires a certain mechanical strength and is recycled for many times.

Packed in carton

1. Are you a businessman or a manufacturer?

We are a company, we have our own factory

2. How long is your delivery time?

Negotiable

3. Can the product be customized?

Can be customized

4. What is the product packaging?

Carton or according to customer requirements