Add to Cart

| Reed width | 190,220, 230,240,250,280 (narrow loom);320,340,360,380 (wide loom) |

| Loom driving | driven by on-off magnetoresistive main super-motor |

| RPM | 750 rpm/min (190cm) as designed as utmost, economically 550~600 RPM/min (190cm) |

| Weft insertion rate | 1425 meter/min utmost |

| Yarn scope | short yarn Nm200~Nm3 (Ne120~Ne1.8) Long yarn: 22 den~3000 den(25dtex~3300dtex) |

| Weft color selection | 1~8 colors or freely programmed in terms of different yarn specifications |

| Weft detection | 6 or 8 holes weft detector of double -weft prevention |

| Shedding mechanism | STAUBLI 2658 electronic rotated Dobby, utmostly installed 20 heald frames, or tappet shedding or jacquard shedding |

| Beating-up mechanism | two inside set of conjugate cam beating-up mechanism (narrow loom)three inside set of conjugate cam beating-up mechanism (wide loom) |

| Weft insertion system | unique space linkage weft insertion system1 6mm narrow gripper band,single guiding pilot system30mm wide gripper band, no guiding pilot system (option) |

| Let-off mechanism | Servo motor control, 850 kg gravimetric tension sensor Warm beam discharge mechanism as double back rest |

| Warp beam diameter | 800mm,1000mm |

| Warp Stoppage | 6 row electronic stoppage stand, circular pitch: 30 mm |

| Take-up mechanism | servo motor control, double pressing rollers |

| Utmost take-up diameter | 550mm |

| Batch winder | 1 500 mm (option) |

| Weft density | 4~200 pick/cm |

| Weft finding function | Electronic weft finding, close shed positioning control system |

| Scissors | Mechanic weft cutter Mechanic selvage cutter |

| Net port | Ethernet, USB, serial interface |

| Other functions | Network group control, Remote control diagnosis(option), Water-cooling system(option). |

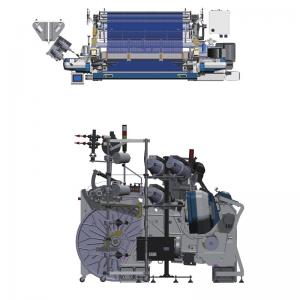

products picture

Product details

Advantages

1.Function: High-speed, Outstanding Quality of Fabrics, high-

Eficiency

2.Production Cost: low power consumption, less maintenance, less

spare parts needed.

3.Investment: low investment, quick profit reward, long-term

performance.

4.Handleability: easy operation and convenience, change fabrics

easily, extensive use.

Our service

Our History

Goodmore tex Machinery Co., Ltd. was established in 2000. Its main

products are jacquard machine, trademark machine and carpet machine

parts.

In 2005, goodmore tex Machinery Co., Ltd. began to export to

foreign countries, and our products entered the EU market.

In 2008, goodmore tex Machinery Co., Ltd. began to be a supplier of

some small textile mills in China.

In 2009, goodmore tex Machinery Co., Ltd. began to cooperate with

some famous foreign textile mills. We provide some textile

machinery and spare parts.

In 2010, we expanded the plant.

In 2012, goodmore tex Machinery Co., Ltd. passed the ISO quality

system certification.

In 2014, the factory moved to Gaoli Auto Expo City, Huishan

District, Wuxi City. In addition, we added some textile spare parts

and officially began mass production.

Our exhibition

Certifications

FAQ

1.Q:Are you a factory or trading company?

A:Yes,we are trading company and we also have own factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Gaoli Auto Expo City,Huishan Area, Wuxi, Jiangsu, China,You can fly to Shang hai airport.

3.Q:Where is your main market?

A:In recent years,our main markets are in Asia, Europe ,Noth America.

4.Q:What is the delivery time of your products?

Usually, the delivery time is 5 working days depending on your purchasing quantity.

5.Q:Can I get free samples from your factory?

A:Yes,of course,we are honored to offer your samples under $10 .however, freight you pay.

6.Q:How does your factory do regarding quality control?

A:Quality is priority.we always attch great inpotance to quality controlling from the very beginning to the very end. Our factory has gained IS09001

certification.

7.Q:If products have some quality problem, how would you deal with?

A:We will responsible for all the quality problem if this had happened.