Add to Cart

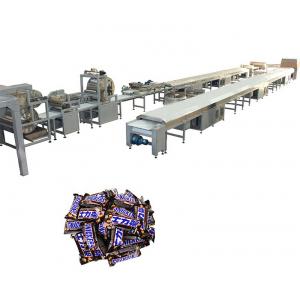

Healthy Snack Stainless Steel Chocolate Bar Production Line

Products Description

The production line is mainly used for producing producing

different kind of bars with or without chocolate coating. The

multi-functional production line is consists four section: cooking

and mixing ; bar forming unit (including sheet forming/caramel

depositing/nuts mixing/cooling/slitting and guillotine); chocolate

enrobing and cooling unit; automatic conveying and flow packing

unit. The cooking and mixing equipments are flexibility and

different base on different technology for different types of bars;

the bar forming section can be used for various kinds of materials

such as fondant, aerated mass, caramel or mixed cereal, praline,

condensed fruit, jelly etc..The universal bar forming principle is

that bar core materials first sheeted by chilled roller, and then

combined with nuts to cooling, slitting and guillotine to get bar

shape and then move to the chocolate enrobing line which optional

unit for chocolate coating products.

Parameters

Model | COB400 | COB600 | COB800 | COB1000 | TTP5000 |

Capacity | 400kg/h | 600kg/h | 800kg/h | 1000kg/h | 1200kg/h |

Steam Requirement | 300kg/h, 0.2-0.8MPa | 600kg/h, 0.2-0.8MPa | 900kg/h, 0.2-0.8MPa | 1200kg/h, 0.2-0.8MPa | 1500kg/h, 0.2-0.8MPa |

Compressed Air Requirement | 0.9m3/min; 0.6MPa | 1.2m3/min; 0.6MPa | 1.5m3/min; 0.6MPa | 1.8m3/min; 0.6MPa | 2.1m3/min;0.6MPa |

Working Condition | 18-25℃ temperature humidity 55% | ||||

Workshop Size | 28*4.5*>2.8m | 35*5*>3m | 38*6*>3.2m | 45*8>3.5m | 48*5>3.8 |

Electric Power Needed | 65kW/380-220V | 90kW/380V-220V | 110kW/380-220V | 135kW/380-220V | 140kW/380-220V |

Weight Of Machine | 17500kg | 20500kg | 23500kg | 26500kg | 28500kg |