Add to Cart

1. Applications for Single Inlet Centrifugal Fan for Boiler

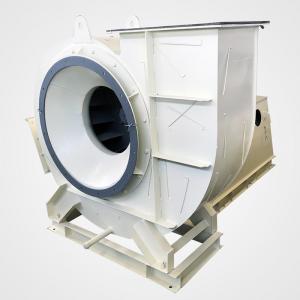

4-72-NO10C/30KW Centrifugal Ventilator Channel Blower Kiln Dust Exhaust Ventilation

The 4-72 centrifugal fan is used as indoor ventilation for general

factories and large buildings. It can be used as input gas or

output gas. Air and other gases that are not spontaneously

combustible, harmless to the human body, and non-corrosive to steel

materials. No viscous substances are allowed in the gas, and the

dust and hard particles contained in it are not more than 150mg/m3.

Gas temperature: no more than 80°C.

The 4-72 centrifugal fan is the earliest fan used in my country,

but it is also the most common fan. From high-rise buildings to

underground railways, from boiler blasting to factory ventilation,

4-72 fans can be seen everywhere .

☆Type of fan

Viewed from the side of the motor, the impeller that rotates

clockwise is called a right-handed fan, which is represented by

"right"; the impeller that rotates counterclockwise is called a

left-handed fan, which is represented by "left".

The outlet position of the fan is expressed by the angle of the air

outlet of the casing. 4-72 type fans №2.8~6 are all made into one

type when they leave the factory, and the user can install them in

the required position according to the requirements, and there is

no need to specify when ordering. Among them, the adjustment range

of the air outlet position of №2.8 is 0°~255°, and the interval is

45°; the air outlet positions of №16 and 20 are made into three

fixed positions of 0°, 90°, and 180°, which cannot be adjusted, and

must be specified when ordering .

There are four kinds of fan transmission modes: A, B, C, and D:

among the 4-72 type fans, №2.8~6 adopts A type transmission, №8~12

adopts C and D type transmission, and №16~20 adopts B type

transmission .

☆The structure of the fan

№2.8~6 of the 4-72 type fan is mainly composed of impeller, casing,

air inlet, motor and other parts. №8~20 has not only the

above-mentioned parts, but also a transmission part.

(1) Impeller: It is composed of 10 backward inclined airfoil

blades, a curved front disc and a flat rear disc. It is made of

steel plate and has been corrected by dynamic and static balance.

The air performance is good, accurate and the operation is stable.

(2) Shell: made into two different types. Among them, the casings

of №2.8~12 are made as a whole and cannot be disassembled. The

casings of №16~20 are made into three open types. In addition to

being divided into two halves along the middle horizontal plane,

the upper half is vertically divided into two halves along the

center line. , connected with bolts.

(3) Air inlet: It is made as a whole and installed on one side of

the fan. The section parallel to the axial direction is a curved

switch. The function is to make the airflow enter the impeller

smoothly, and the loss is small.

(4) Transmission: It consists of a main shaft, a bearing box, a

flow bearing, a pulley or a coupling.

Flow rate: 20~500m3/s, pressure range: 2000~20000 PA, gas temperature is 200℃.

3. the main purpose

Widely used in boiler ventilation, energy recovery, environmental dust removal, desulfurization and denitration conditions. "

Xinxiang SIMO BLOWER Limited Company which was founded in 1995,

mainly designs and manufactures Centrifugal fans and Axial flow

fans which are applied to industrial systems, which is the senior

member of China General Machinery Industry Association. SIMO BLOWER is one of the main large fan manufacturers in Central

China, whichcovers an area of 100,000 square metres, owns more than 200

employees and the production capacity of 15000 sets one year.

There is an advanced Air flow Test Laboratory in our company. We

master mature fan designing, testing, manufacturing technology, and

can design and manufacture multipurpose fans according to users'

requirements. So, we are able to meet users' complex and

professional applications. SIMO BLOWER's products have been widely

used in thousands of customers' industrial systems, such as

Coal-fired power, Metallurgy, Papermaking, Cement and Glass

production, Chemical industry, Material handling, Sewage treatment,

Waste incineration, Subway ventilation, Industrial boiler and Dust

removal systems etc.