Product Details

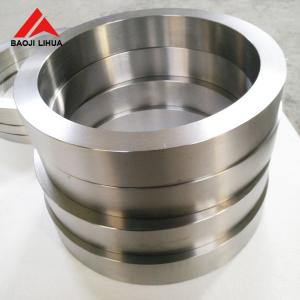

Chemical Titanium Seamless Rolled Rings Titanium Forged Ring For

Industrial

In the industrial world, forged Titanium is valued for having a

very attractive combination of properties such as high strength,

low density, resistance to elevated temperatures and a high

corrosion resistance. It has become one of the most popular metals

in the marine and aerospace industries due to its resistance to

corrosion, particularly in seawater and chlorine environments.

Titanium Forged Ring

| Product Names | Dimensions(mm) | Grade | Standards |

| Outer Diameter | Inner Diameter | Height | Thickness |

| Ring | 200~400 | 100~300 | 35~120 | 40~150 | GR1,GR2, Gr5,Gr7,Gr12 | ASTM B381/AMS4928 |

| 400~700 | 150~500 | 40~160 | 40~250 |

| 700~900 | 300~700 | 50~180 | 40~300 |

| 900~1500 | 400~900 | 70~250 | 40~400 |

| Grade | State | Tensile strength(min) | Yeild strength (min) | Elongation (%) |

| Ksi | MPa | ksi | MPa |

| GR 5 | (M)Annealed | 130 | 895 | 120 | 828 | 10 |

| GR 7 | (M)Annealed | 50 | 345 | 40 | 275 | 20 |

| GR 9 | (M)Annealed | 90 | 620 | 70 | 438 | 15 |

| GR 12 | (M)Annealed | 70 | 438 | 50 | 345 | 18 |

Dimension | OD(Max 6000mm)×ID(Max 5900mm)×L(max length 1000mm) |

Titanium Grade | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

Certification | ISO 9001:2015 & Gold suppier on ALIBABA, Material Mill Test

Report |

Standard | ASTM B381, ASME SB381, AMS, MIL, DIN, BS, JIS, GB/T, ISO, etc. |

Specification | Customized as request |

Process | Forged , Rolling , Grinding, cold press molding |

Type | Including titanium seamless rolled rings, forged rings, and casted

rings

The process for seamless rolled forged rings involves cutting a

hole out of the forging material and rolling it into a thin ring.The rolled forged rings offer concentrically improved rings with

smooth surfaces as compared to plate burn-outs, or butt welded

rings |

Application | 1. Electroplating;

2. Chemical engineering & Petrochemical technology; |

Pictures with more detail

Forged & Rolled

Package & Delivery details

---1.Wrapping each Goods, prevent damage surface of goods in the

long-distance transportation

---2.Inside the box stuffed with pearl cotton and sponge.To prevent the goods shaking in the long-distance transportation.

---3.outside is standard plywood case.

---Accept customer requirment

Make sure that each package is tailor-made for you.ensure when you get the goods no damaged.

Shipment by sea,by air,by express(Fedex,DHL,TNT)

Other Service

- In stocks with short delivery time.

- Strict control from raw materials till products finished,100%

Ensure the quality.

- Support OEM,Customized design,If you are not sure what type of you need for your project, we were

glad to help.

- One on one after service.

- Original mill sheet test reports EN 10204.3.1 is available.

- Support The third party testing and professional inspection

Company Profile

Baoji Lihua Non-ferrous Metal Co., Ltd. was established in 2006.

The company relies on theadvantages of Baoji industry and its

strong technical support. It has been engaged in theproduction and

sales of non-ferrous metals such as titanium, tantalum and nickel

for many years.

The factory covers an area of 800 square meters. The factory has

strong technical equipment. There are more than 20 sets of CNC machines, milling and drilling

machines, and the annualproduction value is more than 30 million CNY.

The company's product is high quality and stable for many years,

and it has obtained the Certification ISO 9001:2015, BV audit certification.

The company has been focusing on the improvement and stability of

product quality for many years. Based on the business concept of maximizing customer

service, we warmly welcome you to come for advice and business negotiation!