Add to Cart

3.6KJ / m³ Notch Impact Strength 0.47g / cc Bulk Density SLS Powder 3D Printer

Product Introduction Of SLS Powder 3D Printer:

The ultra-narrow powder particle size distribution improves the

flatness of the scraper, and the high bulk density ensures the

actual density of the workpiece.

According to the performance of laser sintering, the product is

modified first, and then classified to ensure the utilization rate

of powder back.

The softening point is close to the melting point, and the powder

preheating temperature range in the molding equipment is wide.

Good crystallinity, stable size, small thermal deformation.

The particle size distribution of the multi-particle powder is from

0.08 to 0.2mm in height.

Technical Data Of SLS Powder 3D Printer:

| Material performance items | Value | Units | Test standard | |

| Actual density of material | 1.37 | g/cc | ||

| Molding shrinkage | 0.1~0.3 | % | ||

| Loose density | 0.71 | g/cc | ||

| Particle size Distribution | D90 | 52 | um | |

| D50 | 38 | um | ||

| D10 | 25 | um | ||

| The density of fabrication | 1.24 | g/cc | ||

| Melting point | 230 | ℃ | ||

| Softening Point | 200 | ℃ | Ordinary pressure | |

| Tensile strength | 130 | Mpa | ASTM D638 | |

| Elongation at break | 36 | % | ||

| Notch impact strength | 6 | KJ/m³ | ISO 179 | |

| Material preheating temperature | 160~200 | ℃ | ||

| Molecular weight of material | 55000~ | 80000 | ||

Used for industrial production of high mechanical parts, hand mold, wax mold before casting.

| Material performance items | Value | units | Test standard | |

| Actual density of material | 1.03 | g/cc | ||

| Molding shrinkage | 0.4~1.0 | % | ||

| Loose density | 0.51 | g/cc | ||

| Particle size distribution | D90 | 72 | um | |

| D50 | 51 | um | ||

| D10 | 27 | um | ||

| The density of fabrication | 0.98 | g/cc | ||

| Melting point | 172 | ℃ | ||

| Softening point | 107 | ℃ | Ordinary pressure | |

| Tensile strength | 49.3 | Mpa | GB/T 1040-2006 | |

| Elongation at break | 40 | % | ||

| Notch impact strength | 3.6 | KJ/m³ | GB/T 1043-2006 | |

| Charpy Non-Notch Impact | 19 | KJ/ m³ | ||

| Material preheating temperature | 160 | ℃ | ||

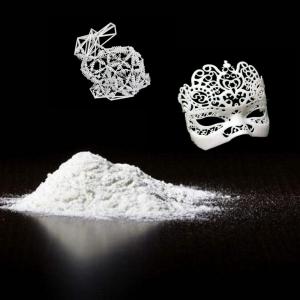

Hand mold, ornamental parts, high surface requirements

| Material performance items | Value | Units | Test standard | |

| Actual density of material | 0.95 | g/cc | ||

| molding shrinkage | 0.4~0.8 | % | ||

| Bulk Density | 0.47 | g/cc | ||

| particle size distribution | D90 | 65 | um | |

| D50 | 55 | um | ||

| D10 | 23 | um | ||

| The density of fabrication | 0.90 | g/cc | ||

| melting point | 178 | ℃ | ||

| softening point | 112 | ℃ | Ordinary pressure | |

| tensile strength | 29.3 | Mpa | GB/T 1040-2006 | |

| elongation at break | 15 | % | ||

| notch impact strength | 3.6 | KJ/m³ | GB/T 1043-2006 | |

| Charpy Non-Notch Impact | 19 | KJ/ m³ | ||

| Material preheating temperature | 160 | ℃ | ||

3D sand casting

Application Of SLS Powder 3D Printer:

Packaging&Shipping Of SLS Powder 3D Printer:

1) 25kg/bag, with composite kraft paper bag

2) Palletizing, suitable for sea and air transportation

3) Shrink film

4) Ton bags

Our Services:

Our company mainly produces plastic powder and plastic powder machine

——Low temperature pulverizer, mixer, screening machine, feeder, air classifier, etc

We have chemical engineers and mechanical engineers to provide you with quality service.

Please tell us your usage or application!

---------We can help you!

Production Machines Of SLS Powder 3D Printer:

If you want to make your own powder, we can help you too. We also produce cryogenic mills, air sorters, sifters, mixers, feeders...