Add to Cart

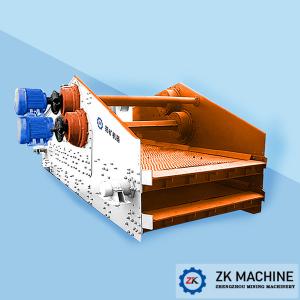

High-frequency Vibrating Screen Price / Small Size Materials Vibrating Screen

Introduction:

High-frequency screen consists of vibration exciter, ore slurry distributor, screen frame, machine frame, suspension springs and sieve, etc..

Our Advantages of Vibrator Screening Equipment:

1. Sieve machine design, ingenious and easy to assemble, one person

can operate the screening machine.

2. Independent and other related brand manufacturers, compared with

a larger screen area and high efficiency of processing capacity.

3. Unique screen structure design, convenient and fast change

screen (only 3 to 5 minutes), in addition, this design allows the

use of a variety of screen (nylon, special dragon, PP nets).

4. The parent network to fully support the fine mesh, so fine mesh

scored a longer life, and reduce the supplies of fine mesh, the

production process and the long time can reduce a lot of cost.

Working Principle of High Frequency Screen:

The straight shaking movement is realizedby two unbalanced gravities of high frequency screen. Two motors drive upperand lower shaft separately do reversed rotation movements. The existing forces,produced by synchronous opposite rotation and formed 30°with screen face, are overlapped. At the same, existing forces inother direction are offset. Then the single direction existing force is formedso that the screen shaking reciprocally along straight line. Because the screenis shaking along overlapped exciting force in high frequency and no shaking inother direction, the screen is working stably.

Sand Screening Specifications:

| Model | Screen square (m2) | Thickness of input material (%) | Capacity (t/h) | Power (kw) |

| GPS-4 | 4.5 | 30%-40% | 15-25 | 0.72 |

| GPS-5 | 5.2 | 30%-40% | 20-30 | 1.1 |

| GPS-6 | 6 | 30%-40% | 24-36 | 1.5 |

| GPS-8 | 8.1 | 30%-40% | 32-48 | 2.2 |