Add to Cart

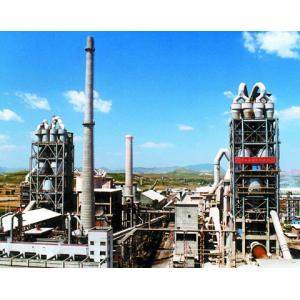

50~3000 TPD Cement Clinker Grinding Plant For Sale

Cement Plant Specifications

50~3000 ton tpd cement plant, turn-key services. Dry process,

rotary kiln

cement production line, clinker grinding plant

Cement plant, cement factory, clinker grinding plant, dry cement plant

Cement production line with 50~3000 ton tpd capacity; turn-key services. dry process, use rotary kiln.

Cement Clinker Grinding Plant with new price

Cement Clinker Grinding Plant Main Materials:Clinker,Gypsum, Additives

ZK Corp is the professional manufacturer of cement equipment, can

offer complete solution for grinding station, and improves

production efficiency, reduces power consumption and

environmentally friendly.

PRODUCTION TECHNOLOGY

After gypsum, clinker and limestone are measured by the belt

weigher, they will be mixed together in accordance with particular

proportions, and then sent to the stable weighing warehouse. During

this process, magnetic metals are removed by the iron remover from

these materials. Then mixed materials will be sent into the rolling

machine to be crushed. After crushed, they will be sent to the

powder separator, in which coarse powder will be sent back to the

grinding mill while the fine one will be sent to the elevator for

finished products. Finally, they will be sent to finished product

storage. Meanwhile, dusty gas from the grinding mill will be

purified by the environmental protection equipment before

discharged into the atmosphere.

CONFIGURATION

| No. | Item | Unit | Closed circuit production | ||||

| 1 | Factory capacity | ×10³t/a | 100 | 160 | 250 | 350 | 500 |

| 2 | Main material usage | ||||||

| ① | Clinker | t/a | 80000 | 128000 | 200000 | 280000 | 400000 |

| ② | Gypsum | t/a | 5000 | 8000 | 12500 | 17500 | 25000 |

| ③ | Pozzolana | t/a | 15000 | 24000 | 37500 | 52500 | 75000 |

| 3 | Energy consumption | ||||||

| ① | Fresh water | t/a | 4000 | 7000 | 9000 | 12000 | 17000 |

| ② | Electrical | kWh/a | 3600000 | 5700000 | 8500000 | 1200000 | 1.7E+07 |

| 4 | Layout transportation | ||||||

| ① | Land area | ㎡ | 15000 | 18000 | 20000 | 22000 | 24000 |

| 5 | Project invest | ||||||

| ① | Production line total invest | Ten | 600 | 1000 | 1500 | 2000 | 2850 |

| thousand | |||||||

| 6 | Workers | 30 | 35 | 35 | 35 | 35 | |

| 7 | Main equipment | ||||||

| ① | Ball mill | Φ2.2×6.5m | Φ2.4×11m | Φ3×11m | Φ3.2×13m | Φ3.5×13m | |

| 14t/h | 24t/h | 35t/h | 50t/h | 70t/h | |||

| 380kW | 630kW | 1250kW | 1600kW | 2000kW | |||

| ② | Belt conveyor | B500 | B650 | B650 | B800 | B1000 | |

| ③ | Mill outlet bucket elevator | TH315 | TH400 | NE100 | NE150 | NE200 | |

| ④ | Air classifier | NHX400 | NHX600 | NHX700 | NHX800 | NHX1000 | |

| (Osepa N250) | (Osepa N500) | (Osepa N750) | (Osepa N1000) | (Osepa N1500) | |||

| ⑤ | Bag filter | PPC32-4 | PPC32-6 | PPC64-5 | PPC64-6 | PPC64-7 | |

| (PPC64-6) | (PPC96-7) | (PPC96-2×5) | (PPC96-2×6) | (PPC96-2×10) | |||

| ⑥ | Finished production bucket elevator | TH250 | TH315 | NE50 | NE100 | NE100 | |

| ⑦ | Screw conveyor | LS400 | LS400 | LS500 | - | - | |

| ⑧ | Packer | Three nozzle | Four nozzle | Six nozzle | Eight nozzle | Eight nozzle | |

| ⑨ | Belt weigher | B500×2000 | B650×2500 | B800×2500 | B800×2500 | B1000×3500 | |

FAQ:

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: What should I take care when using the machine?

A: Keep the machine away from thinner and other chemical liquid.

Q: How to maintain the machine?

A: Check the connection part and clean the screen frame regularly.

Q: How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.