Add to Cart

Product Description

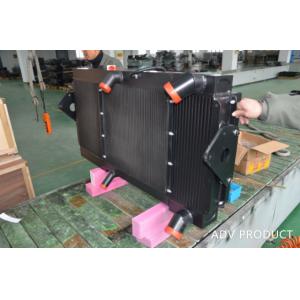

Our All-Aluminum bar plate heat exchangers are manufactured by atmosphere controlled furnace brazing to ensure the highest quality and performance.

All-aluminum construction means lighter weight and improved heat transfer over traditional radiators (copper/brass).

Suitable for a wide range of applications, single or dual pass, down flow, or cross flow designs can all be usd in a full range of dimensions to meet your specific needs. Welcome to contact us to custom your mining machinery cooling solutions.

Application:

Mining machinery all cooling solutions

Product Feature

| Technology | •Well Controlled Vacuume Brazing | |

| • Skillful Arc Welding | ||

| • Precision Machining & Special Shroud Fabrication | ||

| Experiences | Rich Experence with OEM customer to design and manufacturing the best performance heat exchangers for you | |

| Quality | 1. Raw-material quality control; 2.100% leak test control for every unit; 3. Inspect dimension, accessories and appearance before packing | |

| Delivery | 7~15 Days | |

| Service | • Pre-Sales Service can offer you tec guide and consulting support | |

| • After-Sales Service 7days *24 hours on line with 12 month global warranty | ||

Research & Development

1.Thermal Modeling system

2.Analytical Tools

3.Solid modeling

4. Failure Mode and Effects Analysis (FMEA)

LAB & Test

1.Leak Test of Every before shipment Unit

2.Performance Test

| Performance Test: | Compressed Air System | Water Glycol System | Water Glycol System |

|---|---|---|---|

| Flow: | 0-48Nm3/min | 400L/min | 600L/min |

| Temp: | ≤200°C | ≤100°C | ≤110°C |

| Max. heating power: | 110KW | 180KW | 240KW |

3. Salty Spay Test

we can offer C5 standard preservative treatment preservative treatment, please contact us fr more information

Purchasing Guide

You just need to tell us your thermal requirements so we can customize the oil cooler air cooler water cooler radiator for your equipments.

| Oil parameter | Fluid | |

| Flow | ||

| Inlet temperature (℃) | ||

| Cooling power (kw) | ||

| Max. allowable pressure drop | ||

| Max. work pressure (MPa) | ||

| Air parameter | Flow | |

| Inlet temperature (℃) | ||

| Cooling power (kw) | ||

| Max. allowable pressure drop | ||

| Max. work pressure (MPa) | ||

| Cool air parameter | Flow & Pressure curve | |

| Inlet temperature (℃) | ||

| Air trace | ||

| Mounting | Max overall dimension | |

| Location of connections | ||

| Requirement of structure | ||

| Working condition | ||

Be free to contact us if you need any further supporting, thank you!