Product Details

Description of Carbide Crashed Grits:

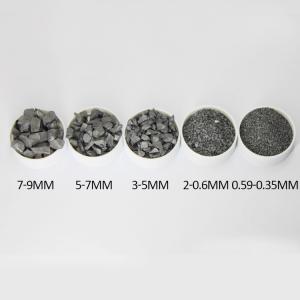

Different Size Hardface Material Carbide Powder Yg8

Tungsten carbide grits also called tungsten grits,carbide grits,it

is used to welding or solder onto a steel body, to increase thewear

resistance properties. For example, if a steel cutter can cut 24

hours without grits, it will cut 240 hours after with the tungsten

carbide grits.

Product Name | pure Carbide Crashed Grits |

Material | 99.90% tungsten |

Color | Golden,Sliver |

Size | 0.35~9mm,customized accepted |

Surface | Polish, Alkali cleaning,Chemicial cleaned |

Standard | ASTM B760, ASTM B777 |

Process | Rolling, Forging, Sintering |

Customized | Our factory supports Size, Coating, Shape, Logo, Sample Test etc.

customization. |

Application | 1.High melting point 2.High- density

3.high temperature oxidation resistance

4.long service life 5.resistance to corrosion. |

Szie Chart of Carbide Crashed Grits:

Application of Carbide Crashed Grits:

The tungsten carbide grits is suitable for hard facing material. 1

mesh to 12 mesh: used for wear-resistance electrode and mace

electrode;

10 mesh to 60 mesh: used for saw blade or play a role of

wear-resisting welding in the metal surface.

- 1) Ceramic, metal lapping, and polishing applications

- 2) Slicing of silicon carbide wafers

- 3) Rock and stone polishing and engraving

- 4) Slicing, lapping,and polishing glass and germanium wafers

- 5) Lapping of piston rings and gears

- 6) Grinding of nonferrous materials

- 7) Finishing tough and hard materials

- 8) Bonded abrasive tool applications

- 9) Glass etching and glass carving industries

Advantages of Carbide Crashed Grits:

- High thermal conductivity rating of 100 W/m-k

- Extremely hard : Mohs 9.1 or 2550 Knoop. Harder than aluminum oxide

- Blocky grain, will splinter as it breaks down, fast cutting

speeds,great for recycling

- High strength at elevated temperatures

- Great for glass frosting & engraving,stone carving &

etching, rock tumbling

- Grades 16 through 1500 available

Company Profile

Joint carbide co.,ltd was established on January 21, 2019, as a sales branch established

by Zigong joint carbide co.,ltd in Chengdu.Our company covers

20,000 square meters was a high-tech enterprise integrating

research, development, production and sales of cemented carbide

products and cemented carbide rotary burrs,carbide tire

studs,carbide repair tire stud,carbide particles & composite

welding rods.

The company is committed to providing high-precision, high-speed

and efficient metal grinding solutions and services for the

machinery manufacturing industry. The company introduced the most

advanced international five-axis five-linkage CNC tool grinder,

three-coordinate tool detector and other equipment from Germany.

The aim is to produce high-quality, internationally competitive

products using internationally advanced equipment. At present, our

company has become the largest rotary file production base in the

country, with a mature R&D team and management team in China,

and a stable supply chain.

As a metal cutting tool, the rotary file has been exported to

Europe, North America, South America and a small number of

Southeast Asian countries.A few days ago, the company has completed

the accumulation of various infrastructure and technology research

and development. Since 2020, our company has added 200 five-axis

and five-linkage rotary grinders. By 2023, our company will invest

a total of 400 five-axis and five-linkage rotary grinders. Grinding

machine (total value 150 million yuan). By then, our company will

become the world's largest supply base for rotary files.We have the

world's advanced raw material cemented carbide formula technology,

the most optimized advanced manufacturing process, and the

largest-scale production equipment.

Our Brands: