Add to Cart

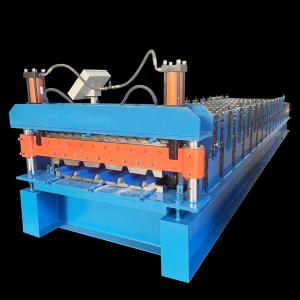

The Double Layer Roll Forming Machine is a versatile and user-friendly solution for producing high quality corrugated roofing tiles. With a forming width of 1000-1200mm and a power of 4KW, this machine is designed for efficient and durable operation, delivering exceptional results for both trapezoid and corrugated roofing tiles.

The Double Layer Roll Forming Machine is a cutting-edge product that combines advanced technology with precision engineering to create a highly efficient and reliable solution for producing trapezoid and corrugated roofing tiles. It features a PLC control system, allowing for easy operation and flexibility in producing any length of roofing tiles.

1. High Precision: The Double Layer Roll Forming Machine is designed to produce roofing tiles with high precision, ensuring a perfect fit and uniform appearance for every tile.

2. Efficient: With a power of 4KW, this machine is designed to work quickly and efficiently, reducing production time and increasing output.

3. Durable: Made with high-quality materials, the Double Layer Roll Forming Machine is built to withstand the rigors of continuous production, ensuring long-lasting performance and minimal downtime.

4. User-Friendly: The PLC control system makes operating the machine simple and easy, reducing the need for technical expertise and increasing efficiency.

5. Automation: The machine is fully automated, reducing the need for manual labor and increasing productivity.

6. Flexibility: With the ability to produce any length of roofing tile, the Double Layer Roll Forming Machine is a versatile solution for various roofing projects.

7. Versatile: The machine can produce both trapezoid and corrugated roofing tiles, providing a one-stop solution for all roofing needs.

The Double Layer Roll Forming Machine is an essential tool for any roofing tile production facility. With its high precision, efficiency, durability, and user-friendly design, it offers a cost-effective and reliable solution for producing top-quality trapezoid and corrugated roofing tiles. Invest in the Double Layer Roll Forming Machine today and take your roofing tile production to the next level.

| Double Layer Roll Forming Machine Technical Parameters | |

|---|---|

| Product Name | Corrugated Roofing Tile Machine |

| Product Type | Double Layer Roofing Tile Machine |

| IBR and Corrugated Roof Sheet Machine | |

| Roller Stations | 18-20 |

| Power | 4KW |

| Forming Thickness | 0.3-0.8mm |

| Machine Size | 7.5m*1.2m*1.5m |

| Machine Weight | 6.5T |

| Cutting System | Hydraulic Cutting |

| Roller Material | 45# Steel |

| Voltage | 380V/50HZ/3Phase |

| Control System | PLC |

| Roller Diameter | 70mm |

FMS Double Layer Roll Forming Machine is a top-of-the-line product that is designed and manufactured in China. It is a highly efficient and reliable machine that is perfect for producing high-quality corrugated roofing tiles and trapezoid roof sheets. With its double layer design, it can greatly improve work efficiency and reduce production time.

The FMS Double Layer Roll Forming Machine is a highly versatile and efficient machine that can be used for producing corrugated roofing tiles and trapezoid roof sheets. Made with high-quality 45# steel, the rollers of this machine are durable and can withstand heavy use. The machine has a compact size of 7.5m*1.2m*1.5m and a weight of 6.5T, making it easy to transport and install.

This product is widely used in the construction industry for producing corrugated roofing tiles and trapezoid roof sheets. These roofing materials are commonly used for commercial and residential buildings, as they are durable, cost-effective, and aesthetically pleasing. The FMS Double Layer Roll Forming Machine is perfect for companies that specialize in roofing material production or for contractors who need to produce roofing materials on-site.

The FMS Double Layer Roll Forming Machine is designed to perform a simple and efficient production process:

The FMS Double Layer Roll Forming Machine is an essential product for any company or contractor in the construction industry. With its high-quality production, efficient operation, and durable construction, it is a valuable investment that can greatly improve work efficiency and increase profit margins. Backed by CE certification and a minimum order quantity of 1, this machine is a reliable and guaranteed choice for producing top-quality corrugated roofing tiles and trapezoid roof sheets.

This Double Layer Roll Forming Machine will be packaged in a sturdy wooden crate to ensure its safety during transportation. The machine will be wrapped with protective materials and securely fastened to prevent any damage. All necessary components and spare parts will also be included in the package.

The machine will be shipped by sea, air, or land, depending on the customer's preference and location. We will work with reliable and experienced shipping companies to ensure timely and safe delivery of the product. The shipping cost will be determined based on the chosen mode of transportation and the destination.

Once the machine reaches its destination, our team will provide assistance with the unpacking and installation process. We will also provide detailed instructions for proper use and maintenance of the machine.