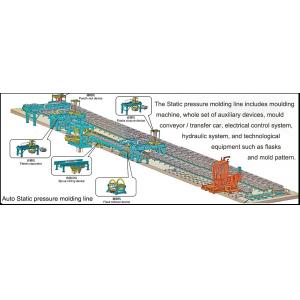

Automatic Moulding Line / Automatic Static Pressure Moulding Line

with KW technology

Introduction:

It is comprised of moulding, core setting & flasks closure,

pouring, cooling and shakeout five sections. There are so many

working systems: Manual, automatic, non-moulding, no filling-sand,

no shake-out , cooling duct selection and other working systems.It is comprised of moulding, core setting & flasks closure,

pouring, cooling and shakeout five sections. There are so many

working systems: Manual, automatic, non-moulding, no filling-sand,

no shake-out , cooling duct selection and other working systems.

Product:

Automatic Static pressure molding line includes moulding machine, whole set

of auxiliary devices, mould conveyor / transfer car, electrical

control system, hydraulic system, and technological equipment such

as flasks and mold pattern.

Auxiliary devices of moulding line include punch-out device, flasks

separator, flask lifting, lowering and transfer device, flask

rollover device, cleaning device, flasks closure device, flasks

fastening & loosening device, vent hole drilling device and

sprue milling device, which can carry out auxiliary processes of

the whole moulding line.

Application:

With moulding sand can be used for the production of grey iron,

nodular iron, malleable iron, steel, aluminium and other

non-ferrous metals. Patterns made of metal can be used.

Suitable for volume production of top grade castings, it has been

widely applied in production of automobile castings and other grey

cast iron, ductile iron and steel castings.

OEM welcomed!!!

For any interest, just contact us.