Add to Cart

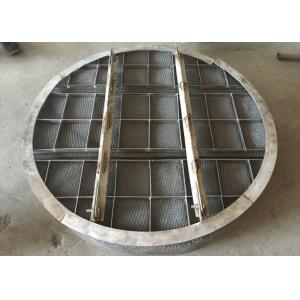

SS304 Knit Mesh Vapor Liquid Separator With Supporting Ring And Beam

Vapor-liquid separator

It is used to separate mixture of vapor liquid in some industrial applications. Sometimes a vapor-liquid separator may also referred to as a flash drum, knock-out drum, compressor suction drum or compressor inlet drum. It is usually called mist eliminator when used to remove suspended water droplet from air stream.

Normally, in the vertical vessels, the liquid drops to the bottom, where they are withdrawn, as the force of gravity. But in low gravity environments like a space station, the gravity is not usable effectively. At this time, centrifugal force needs to be utilised in a spinning centrifugal separator to drive liquid droplets to the outer edge of the device while gas migrates to the centre.

In either way of separation, the gas outlet can be surrounded by a spinning mesh screen or grating. If any droplets occasionally reach the outlet, they will strike the grating, be accelerated and thrown away from the outlet.

The vapor goes through the mist eliminator at a designed velocity which minimizes the re-entrainment of any liquid droplets.

The feed to a vapor-liquid separator may also be a kind of liquid which is being partially or totally flashed into a vapor when it enters the device.

Demister mesh density and its applications

Mesh density (stainless steel) | Application |

| 50 kg/m3 | Heavy fouling, e.g. evaporators |

| 80 kg/m3 | Moderate fouling, e.g. vessel boilers |

| 110 kg/m3 | Light fouling |

| 145 kg/m3 | Heavy duty, e.g. oil and gas separators |

| 170 kg/m3 | General purpose, not totally clean |

| 195 kg/m3 | Optimum efficiency & pressure drop |

| 240 kg/m3 | High density with high separation efficiency |

| 112 kg/m3 | General purpose, clean service |

| 145 kg/m3 | Find droplet removal in clean service |

Other engineering details like material and wire diameter are not shown here. Welcome your contact for more info!

When properly designed demister pad vapor liquid separators can give efficiency up to 99.9% with minimal pressure drop. Normally demister pads can remove droplets down to 5 microns and lower with a free volume of up to 99% and a surface area of up to 1940 m2/m3. Due to high value of free volume the pressure drop across the demister pad is sufficiently low in most applications.

Vapor-liquid separator are very widely used in a great many industries and applications:

Paper mills

Flare stacks

Oil refineries

Gas pipelines

Air conditioning

Compressor system

Soil vapor extraction

Refrigeration systems

Geothermal power plants

Natural gas processing plant

Combined cycle power plants

Steam condensate flash drums

Petrochemical and chemical plants

Package & shipping of demister vapor - liquid separator: