Add to Cart

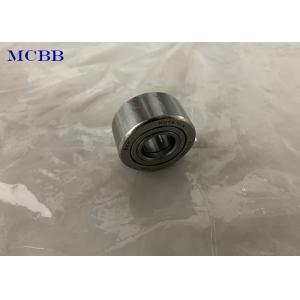

McGill CF 2 1/4 CF2 1/4S CF2 1/4B NUTR 17A Cam Follower Track Roller Bearing

Description,

1. The eccentric stud provides a way to adjust the radial position

of the bearing, which can improve the load balance in the bearing

combination application. The load balancing of the cam follower

bearing can reduce premature damage due to bearing overload,

thereby saving operating costs, reducing the requirements for

precise mounting hole position tolerances, and providing the

ability to readjust the bearing position as the raceway wears. The

eccentric bushing is installed on the stud by press-fitting and is

not hardened to keep the pin or set screw permanently locked.

2. The bushing type is also one of the MCGILL cam follower

bearings. Non-metallic bushings support the load by sliding. For

non-food-grade applications that are not convenient for

relubrication or that do not allow grease contamination in the

process, non-metallic bushings can reduce the bearing The need for

lubrication. Its maximum allowable continuous operating temperature

is 200 ° F. Bushed CAMROL bearings are used in a self-lubricating

mode. However, continuous oil lubrication can be used to reduce

wear rates. It should not be lubricated with grease.

Right front wheel bearing, Specification,

| Details: | |

| Name | Cam Follower Needl Bearing NUTR 17A |

| Brand | Mcgill |

| No. | NUTR 17A |

| Quality | High Quality can substitute |

| Size: | Following list |

| Minimum quantity: | 1 piece |

| Precision: | P0, P4, P5, P6 |

| Hardness: | 58 to 62 HRC |

| Seal Types | Open |

| Material: | Bearing steel |

| Cage material | Steel cage |

Feature,

The flange-type outer diameter (OD) of the cam follower can

increase bearing life compared to standard cylindrical cam follower

MCGILL bearings. Cams help distribute stress on the outer ring and

rolling elements due to misassembly or stud bending. The cam also

helps to reduce slippage of the outer ring in swivel or rotary

applications. Not all applications take advantage of the flange

outer diameter. Ask the application engineering department for

guidance on your application.

Increasing the diameter of heavy-duty studs and the rod diameter of

heavy-duty stud cam follower bearings increases the diameter of the

studs, which can improve the static load carrying capacity of

MCGILL bearings. Increasing the diameter can reduce the amount of

deflection that can occur when the cam follower bearing is

subjected to radial loads. Due to the increased load carrying

capacity, the maximum recommended load can be 50% BDR. * On

heavy-duty stud bearings, only for CFH inch series.

MCGILL bearings with hexagonal holes (reamed holes) are also

available. The fixing force of the inner hexagonal holes is higher

than the standard screwdriver slot, which is helpful for the

installation and removal of stud cam follower bearings. Hexagonal

characteristics are marked with "B" because it is produced by the

reaming process. For sizes up to 3 ", bearing relubrication from

the flange end must be considered.

If you need bearing quotation, welcome contact us.