Fruity Drink Production Line Full Set Of Cleaning Juicing And Blending Production Line SUS304

Add to Cart

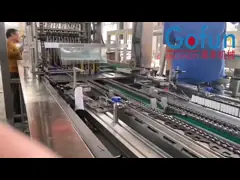

Fruity drink production line Full set of cleaning, juicing and blending production line SUS304

Description

Fruity drink production line can produce from fresh Fruit and vegetable to different kinds of

final product.

The Fruity drink production line is renowned for its ability to transform Fruit and vegetable into tomato paste packaged in aseptic bags within drums. This

comprehensive process encompasses various stages including fresh Fruit and vegetable receiving, washing, sorting, extraction, sterilization, and

aseptic filling systems. The result is high-quality tomato juice

stored in aseptic bags within drums, ready for further processing.

Key Features of the Fruity drink production line :

- Processing Flexibility: The processing capacity of the production line can be tailored to range from 60 tons per day to 4,000 tons per day, meeting diverse production requirements effectively.

- Crushing Options: Customers have the flexibility to choose between hot crushing or cold crushing methods for fruits and vegetables, ensuring that product specifications and preferences are met efficiently.

- Packaging and Shelf Life: The final fruit and vegetable juice ingredients are carefully packaged in aseptic bags within barrels, guaranteeing a shelf life of up to two years at ambient temperatures. This preservation method maintains the quality and freshness of the products over an extended period.

- Continuous Production Line for Blending: The production line offers a seamless and convenient process for formally blending juices, enabling uninterrupted production cycles.

- High-Quality Materials: Emphasis is placed on using food-grade materials throughout the production line, with a focus on utilizing SUS 304 or SUS 316 stainless steel as per specific requirements. This ensures that stringent product safety and hygiene standards are consistently met.

- Diverse Packaging Options: In addition to aseptic bag filling, the production line presents a range of packaging solutions including metal cans, pouches, stand-up bags, and PET/PP containers. This diversity in packaging options caters to various market preferences and needs.

- Sustainable Practices: By repurposing waste fruits or vegetables as fertilizer, the production process aligns with sustainable practices, promoting eco-friendly resource utilization and reducing waste effectively.

| Raw materials | Fruit and vegetable |

| Final products | Fruity drinks |

| Processing capacity | 60 tons/day to 4000 tons/day |

| Packaging materials | Customer selection |

| Volume | Customer selection |

| Final packaging | Plastic buckets, glass bottles, American plastic bags, tins |

| Production | Customized according to customer needs |

Advantages

The Fruity drink production line from Shanghai Gofun machinery company is running with high effective, water saving, high extracting rate, safety quality control for final product, safety control for operators, etc.

Flowchart

FRESH Fruit and Vegetables ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Fruity drink production line usually include the following equipment and process steps:

Raw material processing system: Fresh fruits are washed, peeled,

deseeded and other pre-processing steps to prepare for the

production of fruit-flavored concentrated juice or fruit-flavored

pulp.

Fruit-flavored concentrated juice or fruit-flavored pulp production

equipment: The processed fruits are made into fruit-flavored

concentrated juice or fruit-flavored pulp through processes such as

squeezing, crushing and concentration.

Beverage preparation equipment: Fruit-flavored concentrated juice

or fruit-flavored pulp is mixed with water, sugar, acidity

regulator, preservatives and other raw materials in proportion to

make the basic liquid of fruit-flavored beverages.

Sterilization and sterilization equipment: The prepared

fruit-flavored beverages are sterilized at high temperature to

ensure the safety of the product and extend the shelf life.

Bottling and filling equipment: The processed fruit-flavored

beverages are put into bottles and packaged after steps such as

washing, filling and sealing.

Packaging equipment: The finished fruit-flavored beverages can be

packaged through packaging equipment, such as small bags, stand-up

bags, metal cans, PET bottles, etc., to meet different sales needs.

Quality inspection equipment: Quality inspection equipment is

installed in the production line to test the appearance, taste,

quality and other aspects of the finished fruit-flavored beverages

to ensure that the products meet the standards.

The above are typical equipment and process steps of the

fruit-flavored beverage production line. Through careful design and

coordination, high-quality fruit-flavored beverages can be produced

to meet market demand and ensure product quality.