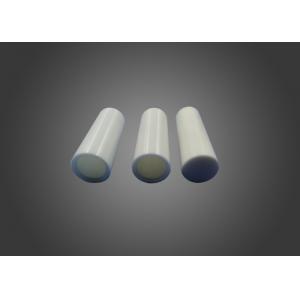

High Insulation Mullite Ceramic Tube Insulator , Bend Elbow 99.7 % Ceramic Products Manufacturing

Add to Cart

99.7% high insulation mullite / pipe rod bend elbow alumina ceramic tube zirconia tube

Product Description

Ceramic Tube Applications

1. Furnace work tubes

2. Kiln furniture, components & accessories

3. Thermocouple protection tubes

4. Heater Support Elements

5. High Temperature Electrical Insulators

6. Extreme temperature measurement components

7. Ceramic Laser components

8. High voltage electrical insulators

| Name | textile ceramics machines |

| Size | Customerized |

| Advantage | High Strength;High Hardness;Insulation;High Temperature Resistance;Oxidation Resistance;Corrosion Resistance;Abrasion Resistance...... |

| Application | Mechanical Seals;Electronics;Instrumentation;Sensor; Transport;Communication;Other occasions areas...... |

95%/99%/99.7% AI203 Ceramic Material Parameters

Item Test Condition 95% AI203 99% AI203 99.7% AI203

Bulk Density (g/cm3) >3.6 3.89 3.96

Maximum Use Temp(°C) 1450 1600 1650

Water Absorption(%} 0 0 0

ROHS Hardness >85 >89 >89

Flexural Strength MPa(psiX l〇3) 20°C 358(52) 550 550

Compressive Strength MPa(psi X l〇3) 20°C 2068(300) 2600(377) 2600(377)

Fracture Toughness Mpa m’/j K(lc) 4-5 5.6 6

Thermal Expansion

Coefficient{lXi〇-6/°C)

25-1000〇 C 7.6 7.9 8.2

Thermal Conductivity

Coefficient(W/m° K}

206C 16 30.0 30.4

Thermal Shock Resistance(°C) ATc 250 200 200

Dielectricity Constant 1MHz.25〇 C 9 9.7 9.7

Dielectric Strength (ac-kV/mm)(acV/mil)

8.3(210) 8.7(220) 8.7(220)

Volume Resistivity(ohm-cm) 100°C >1013 >1014 >1014

Advantages

1) High density

2) Strong

3) Good bending strength and fracture toughness

4) Zirconia ceramics will not wear easily

5) Acid-proof, alkali-proof

6) Mainly used in electronics, electrical appliances, mechanical

and textile industries

7) We can produce zirconia ceramic parts according to clients'

specifications and even according to molds or drawings provided by

the client

FAQ

Q: How long is the delivery time usually?

A:Product delivery is subject to order quantity and processing requirements, and different product delivery times are inconsistent. Generally speaking, the delivery time of 1-2 common product samples is about 35 days.

Q: Is it possible to provide samples?

A: We can supply 1-2 samples, but we do not bear the shipping cost of the samples.

Q: Which payment methods are supported?

A:T/T; credit card. Currently our company supports these two payment methods.

Q: What is the shipping date? How long can I ship?

A1: Shipped within 72 hours after the balance is settled

A2: After the production of the product is completed and passed the

internal inspection of the company, we will send the finished

product image to the customer for confirmation. After the balance

is settled, all the products will be sent to the customer's

designated delivery location.