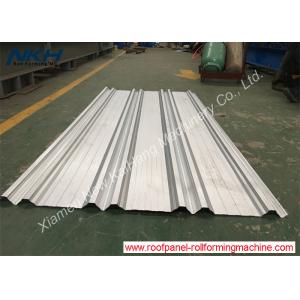

Twin rib metal sheets roll forming m/c, Philippines standard design for roof panel making machine

Add to Cart

Twin rib metal sheets roll forming m/c, Philippines standard design for roof panel making machine

Quick Detail:

- Thickness : 0.4mm-0.8mm

- Material : PPGL metal sheets, 550Mpa

- Input width : 1220mm

- Effective width: 954+/-4mm

- Material weight : 5MT or customized

- Coil inner diameter : 508mm

- Roller material: 45#, CNC laths, hard chrome coated

- Cutting tolerance : ±1mm

Description/Technical Parameter details of complete line:

- 5TX1250mm hydraulic de-coiler with/without coil car

You can adapt to hydraulic un-coiler or manual one as per request, and the un-coiler capacity 5MT, 6MT, 7MT, 8MT, 10MT also as per the coil order, if the un-coiler capacity is above 5tons, it is better equipped with coil cart

- Entry Roller & Manual Pre-shearing device (Un-powered)

To cut off the end of the first or final piece of sheet only

Working thickness: max. 0.8mm

- Roll forming machine with cutting details as below table :

| Production material | Pre-painted Sheets,G550 |

| Thickness range | 0.4mm-0.8mm |

| Coil width | 1220mm |

| Carriage Frame design | Classic wall-plate-frame-design, 18mm wall plate thickness |

| Roll forming steps | 20 steps |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated to avoid the rusty and with high precision |

| Shafts Diameter | Φ75mm/95mm |

| Main motor power | 7.5Kw driven motor with gear box Or higher for high speed |

| Line speed of roll former | 15-18m/min |

| Hydraulic group power | 4.0Kw |

| Material of cutter | Cr12, hear treatment as normal design |

| Electric Voltage Standard | 220V/60Hz/3Ph or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as per customer’s requirements |

- PLC Control System

Siemens brand PLC/touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron brand encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

- Run out table rolled type, 3 units

Machine list:

- Hydraulic un-coiler with 5Tons capacity

- Normal speed roll former

- Hydraulic cutting device

- Run out table

- PLC control systems

Features:

A trapezoidal roof panel roll forming machine is always adjustable for different feeding widths. You can make trapezoidal roof panels with different effective widths from different-width materials.

Profile Drawing/Layout/Equipment reference pictures: