Metal Wall Panel Manufacturing Equipment PE - 900 With High Cut To Length Precision

Add to Cart

Metal Wall panel forming machine with tooling, PE - 900 with high cut to length precision

Application:

This 41-184-920 or PE-900 wall panel was sold to Vietnam and Bangladesh before as PEB company standard design for wall cladding sheets.

Metal sheet roll formers are widely used to produce mainly metal roofing and wall cladding sheets, and the most popular metal sheet roll forming machines in the markets can be found here.

Quick Detail:

- Thickness : 0.4-0.8mm

- Material : G550, pre-painted sheets

- Input width : 1219mm

- Coil ID: 508mm

- Effective width:920+/-4mm

- Material weight: 5Tons cap.

- Driven motor: by 7.5Kw or 11kw motor with gear box or higher

- Cutter Material: Cr12, heat treatment

Machine list:

- 5T*1250mm hydraulic de-coiler as standard design

- Roll former

- Hydraulic cutter

- Run out rack

- PLC control system

Description/Technical Parameter details of complete line:

- 5TX1250mm Hydraulic Un-Coiler

You can adapt to 5TX1250mm Hydraulic Un-Coiler as standard design or you can also use manual one when the budget is limited

- Entry bench & Manual Pre-shearing device

to cut off the end of the final piece of sheet only

Working thickness: max. 0.8mm

- Roll forming machine with cutting details as below table :

| Suitable roll forming material | Color steel sheet or galvanized steel sheet, G550 |

| Thickness | 0.4-0.8mm |

| Coil feed in width | 1219mm |

| Carriage Frame design | Wall-plate-frame-design or stand frame desig |

| Roll forming stages | 24 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75/95mm |

| Main motor power | 7.5Kw with reducer |

| Line speed of roll former | 15m/min or higher |

| Hydraulic group power | 4.0 Kw |

| Cutting material | Cr12, hear treatment |

| Electric Voltage Standard | 415V/50Hz/3PH or as request |

| Major Painting Color | Customized and RAL5015 as standard |

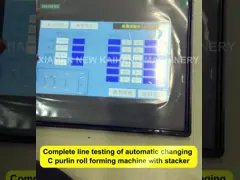

- PLC Control System

Cut to length control

Cut-to-length tolerance≤±1mm

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Schneider brand low voltage electric elements

- Product Rack 3 units, no power rack

Profile Drawing/Layout/Equipment reference pictures: