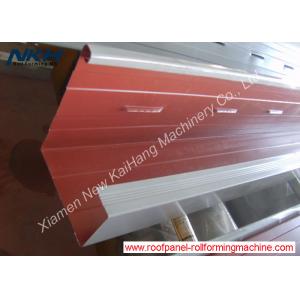

Australia Water Gutter Roll Forming Machine , Gutter Roll Forming Line With End Cap

Add to Cart

Australia water gutter Machine, gutter roll forming line with end cap

Quick Detail:

- Thickness : 0.4-0.6mm

- Material : G550 full hard Galvanized Sheets

- Input width :375mm

- Material weight : 3MT

- Coil inner diameter : 470 mm

- Driven way: by 7.5Kw driven motor

- Cutting way: 4Kw hydraulic pump motor

- Cutting tolerance : ±1mm

Application:

A gutter roll forming machine work with the flashing and downpipe and end cap and support fixing as a water roof systems

This gutter panel is very popular in Australia, exclude the gutter panel, the connecting accessories and end cap also included

Machine list:

- 3T*600mm hydraulic un-coiler

- Roll forming machine

- Hydraulic cutting device

- Run out table

- PLC control cabinet

Description/Technical Parameter details of complete line:

- 3TX600mm Hydraulic Un-Coiler

Hydraulic system for expansion coil-inner-hole with 4 palms

Pump power=1.5KW

Load capacity=3 Ton; Coil Inner – diameter =451-530 mm

Coil outer-diameter=Max. 1500 mm

Coiler Width=Max. 600 mm

- Roll forming machine details as below table :

| Suitable roll forming material | galvanized steel sheet, 55Mpa |

| Thickness | 0.4mm-0.6mm |

| Coil input width | 375mm |

| Carriage Frame design | Wall-plate-frame-design |

| Rolling mills forming stages | 18 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated Option : with roller heat treatment |

| Shafts Diameter | Φ75mm |

| Main motor power | 7.5Kw with reducer |

| Rolling speed of roll former | 15-20m/min |

| Electric Voltage Standard | 415V/50Hz/3PH or as requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as requirements |

- Hydraulic Cutting Device

Stop to cut, Post cut, there is waste

Hydraulic group, pump motor =4.0KW

Cutting tool material: Cr12, Heat treatment

- PLC Control System

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

- Product Rack Un-powered, rolled type, 4 meter long

Profile Drawing/Layout/Equipment reference pictures: