45# Light Steel Stud Roll Forming Machine Metal Roll Forming Machine, IBR Roll Forming Machine

Add to Cart

45# Light Steel Stud Roll Forming Machine Metal Roll Forming Machine, IBR Roll Forming Machine

Quick Detail:

- Thickness : 0.15-0.2mm

- Material : embossed galvanized steel/ aluminum-zinc sheets

- Input width : 750mm

- Effective width: 600mm

- Material weight: 5MT cap.

- Coil inner diameter : 508mm

- Driven way: by driven motor

- Cutting way: by hydraulic power pack

- Cutting tolerance : ±1mm

Machine list:

- Hydraulic De-coiler with breaking device

- Roll former

- Hydraulic cutting device

- Run out table

- Siemens PLC and IOP/ touch screen, Shihlin brand inverter

Description/Technical Parameter details of complete line:

- 5TX1250mm Hydraulic Un-Coiler with coil car

Please refer to the item for details

- Entry Roller & Manual Pre-shearing device (Un-powered)

Smart cut control, to cut off the end of the final piece of sheet only

Working thickness: max. 0.6mm

- Roll forming machine with cutting details as below table :

| Suitable roll forming material | Color steel sheet or galvanized steel sheet |

| Thickness | 0.15mm-0.20mm |

| Coil input width | 750mm |

| Carriage Frame design | Wall-plate-frame-design /New-stand-frame-design |

| Rolling mills forming stages | 16 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated Option : with roller heat treatment |

| Shafts Diameter | Φ75mm |

| Main motor power | 5.5Kw with reducer |

| Rolling speed of roll former | 15-20m/min (Higher speed is available, depends on the specification required by the buyer) |

| Hydraulic group power | 4.0 Kw |

| Material of cutting blade | Cr12, hear treatment/Cr12Mov, heat treatment |

| Electric Voltage Standard | 380V/50Hz/3PH or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as per customer’s requirements |

- PLC Control System

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

- Product Rack Un-powered, 3 units

Features of IBR sheet roll forming machine:

IBR sheet roll forming machine is a common roof sheet roll forming machine, but the finished products are used mainly in South African market.

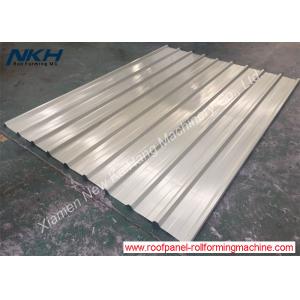

Profile Drawing/Layout/Equipment reference pictures: