Add to Cart

With cooling towers, fill selection is a critical aspect in this regard. High efficiency film fill may seem the most desirable option. However, if poor water quality causes this fill to rapidly foul and plug, it may incur excessive maintenance costs.

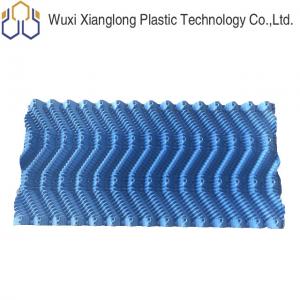

Most cooling towers now utilize film fill to enhance air/water contact. Film fill, as the name implies, induces the cooling water to form a film on the material surface. The filming mechanism maximizes liquid surface area. A guiding principle behind fill design and selection “is to increase air-to-water contact, driving up convection and evaporative cooling while reducing pressure drop in the system”

| Tech Date | |

| Sheet Width(mm) | 500mm |

| Sheet Length | 1000/2000mm/customized |

| Thickness | 0.32-0.6mm/customized |

| Sheet Spacing | 31/33mm |

| Color | grey/white/black |

| Material | PP/PVC/CPVC |

*This type is a film fill system designed for counterflow towers

offering you several distinct advantages.

Crossed corrugations provide the surface area and turbulence to

develop efficient heat transfer. The corrugations inherently

establish uniform fill sheet spacing at 0.75.

*Using MC75 film fill in place of existing splash type fill in

counterflow towers usually means reduced fill height, which

translates into reduced pumping head. MC75 will also provide

greater cooling tower capacity, which means your current

performance level will require less fan energy.

*The fill pack depth(air travel) is variable to provide the proper

heat transfer area within a single fill layer. If another layer of

fill is necessary for situations where additional air travel is

required, it will be limited to only one. Limiting the number of

interfaces between packs minimizes restrictions that usually cause

fill clogging. MC75 counterflow fill can be hung from structural

members or it can be bottom-supported in virtually all counter-flow

cooling towers, regardless of a cooling tower's age or

manufacturer.