Add to Cart

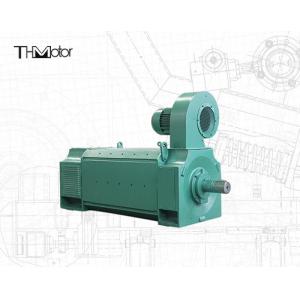

ZFQZ DC Motor With Frequent Starting And Braking

Product overview

ZFQZ type DC motor with frequent starting and braking

Rated power: 30kw - 600KW

Rated voltage: 400V, 440V, 660V

Rated speed 280/430/500/600/750/900RPM

Protection class: IP21S/IP23/IP44

Cooling method: IC06/IC17/IC37/ICW37A86

Insulation class: F

Product introduction:

ZFQZ series DC motor is a series of products developed by our

company on the basis of Z4 series DC motor and drawing on the main

technology of ZZJ-800 series DC motor. The moment of inertia of the

motor is 45% of that of ZZJ-800 series and ZZJ-900 series. and 65%,

adapt to the harsh working conditions of frequent forward and

reverse rotation and frequent starting and braking. The motor has

excellent overload characteristics. Its maximum torque and starting

torque are 112% and 117% times that of ZZJ-800 series and ZZJ-900

series respectively. The weight of the motor is only 65% of that

of the ZZJ-800 series. Comply with the international standard

IEC34-13 "Technical Specifications for Auxiliary Motors for Lifting

and Metallurgy". The external dimensions of the motor are in line

with the IEC72 international standard except for the axial

dimension "B" between the two foot holes. The motor can reach the

main installation dimensions consistent with the ZZJ-800 and

ZZJ-900 series through the base plate, and can be made through

negotiation. The shaft extension size corresponding to ZZJ-800 and

ZZJ-900 series can be replaced by ZZJ-800 and ZZJ-900 series

products.

The cooling method and enclosure protection level of the motor are

as follows:

Cooling method Single-pipe air inlet (IC17); double-pipe air inlet

and outlet (IC37); with air-water cooler (IC86W)

Protection class: IP23S; IP44 ; IP44

2. Motor installation form: horizontal foot installation (1MB3).

The motor can be manufactured with single-shaft extension or

double-shaft extension, and the single-shaft extension motor can be

equipped with a tachogenerator or other speed-measuring device on

the non-transmission side.

3. If the user needs, the thermistor or other overheat protection

components can be embedded in the stator winding of the motor.

4. The position of the outlet box is on the right side of the base

from the transmission side, and can also be on the left or above

the base if the user needs.

Each series of motors

Our aftersales service

Product packaging

Certifications