Product Details

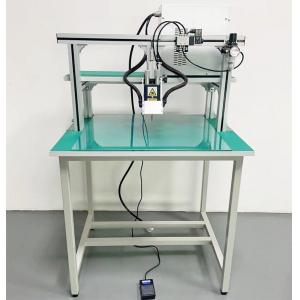

Hot Sale Gantry Lithium Ion Battery Pack Spot Welder Welding

Machine

Characteristics and Advantages

It is mainly used for processing and spot welding of power

management battery, energy storage lithium battery and new energy

battery pack. It has the characteristics and advantages of strong

flexibility, proofing for customers, small batch production and

maintenance of lithium battery pack. It is also one of the

advanced, efficient and reliable spot welding equipment in the

market.

Application Field

Connection between photovoltaic, power battery pack, lithium nickel

hydride battery and nickel sheet alloy sheet aluminum nickel

composite belt, connection between wire and guide sheet, welding of

household appliance parts and wires, connection of hardware

accessories, copper silver products, stainless steel peripheral

joints, bulb foot welding, electronic parts, welding of various

high and low conductive metal alloys, etc.

Product Specification

| Item | Parameter |

|---|

| Welder | 5000A/8000A inverter spot welding power supply(optional) |

| Welding head quantity | 1 |

| Table size | 800 * 600mm |

| Cell type | 18650, 21700, 32650… all types of cylinderial cells |

| Total cell support | 300 - 500 pcs |

| Welding speed | Max 0.35s/spot, 1000 pcs/h |

| Cell link material | Nickel, Nickel-Plated Steel |

| Welding max thickness | 0.3mm |

| Max parameter groups | 99 groups |

| Controller | Microcomputer |

| Driver mode | Pneumatic |

| Cooling method | By air or water (optional) |

| Air pressure | 0.4-0.6 Mpa |

| Power voltage | Single phase 220V/Three phase 380V |

| Power | 4000 W |

| Size | 800L * 600W * 1530Hmm |

| Weight | 100kg |

Product Sturcture

Battery Pack Welding Samples

Spot welding samples

The double side spot welding machine suitable for all types of

cylindrical cells pack and suitable for all shapes of packs. With

high quality 5000A/8000A spot welding power supply, it can weld

thickness from 0.1mm to 0.3mm. Welding spot is beautiful, firm and

good conductivity.

Company Profile

GUANGDONG XWELL TECHNOLOGY CO., LTD. is a high-tech enterprise

specializing in intelligent equipment design, production and sales,

providing mechanical engineering technology design and consulting

services, electronic engineering design and consulting services.

XWELL's core team was established in 2010 and officially

established in June 2014. XWELL relies on South China University of

Technology(SCUT), and the core team is composed of several doctors

and masters from SCUT.

XWELL's main products are battery production line machines, such as

spot welding machine, battery sorting machine, battery sticking

machine, battery capacity grading machine, battery charge and

discharge aging machine, battery general testing machine, and so

on. The main application areas are new energy lithium batteries,

automobiles and other industries, Especially in the fields of new

energy, automotive wiring welding and other fields, XWELL has

accumulated rich engineering experience and mastered a full set of

core technologies, and can provide customers with a complete set of

services from technology to equipment, helping customers to

establish efficient and reliable production lines in the shortest

time .