Add to Cart

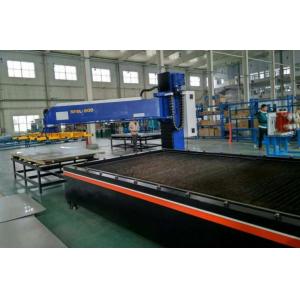

SINGLE-TABLE CNC FIBER LASER METAL SHEET CUTTING MACHINE WITH AUTO LOADING ROBOT

Main technical characteristic,

CNC laser cutting machine adopts gantry-motion structure,CNC system operating, linear guiding, Gear rack and pinion transmission, AC servo motors driving, and vacuum system (both sides), etc. The one-time processing area is 3m*1.5m. Not only that the equipment's design is advanced and reliable, but also that all main components are from both national and international well-known brands.

In particular, we use Shanghai CYPCUT professional laser CNC cutting software for the electrical control system. This special laser CNC system has advantages of high integration, better control precision and more stable operation, therefore, It can meet the requirement of cutting carbon steel plate, Stainless steel plate, aluminum alloy, copper alloy and other materials.

In order to reduce workers, reduce workload and improve work efficiency, a set of automatic feeding Robot is added to the laser cutting machine. Through pre-set program and one key operation, the sheet can be automatically sucked and transported from the stacking table to the cutting platform.

Machine structure and features,

Structure of machine

The Laser cutting machine consists of bed, workbench,cross-beam, sliding seat, CNC operation system, Electrical control system, cooling system, pneumatic system, slag discharge system, dust removal system, Auto Loading Robot and so on.

Main Features of machine

1. Users-friendly operating system CYPCUT, USB port and broadband;

2. Cypcut Programming software and automatic nesting functions;

3. X,Y,Z axes all AC servo driver and motors;

4. CAD/CAM software with powerful nesting function and edge-shared cutting function;

5. Fast-response surface following;

6. Easy operated cutting retract function;

7. Straight line/circular arc interpolation fitting and kerf

compensation functions;

8. Water chillers ensure the laser light path works normally and stablely;

9. Automatic loading Robot feeds sheet from staking platfrom to

cutting workbench instead of persons;

10. Ventilation dust removal device protect working environment

from cutting emissions and metallic vapor;

11. Dust discharging device to facilitate slag discharging.

Main components and brands,

| Name | Brief description | Brand of country |

| Optical system | RAYCUS/IPG | MAX/RAYCUS/IPG |

| Laser power supply | 1kw/1.5kw/2kw/3kw/6kw | MAX/RAYCUS/IPG |

| Autofocus cutting head | Special autofocus cutting head for optical fiber | WSX/Raytools/Precitec |

| Dedicated cooling system | Double circulation system, heat exchange titanium tube, over temperature alarm, flow protection. | Wuhan Hanli/Tongfei |

| Mechanical transmission system | Taiwan Hiwin high-precision high-speed rail Taiwan YYC rack and Pinion | Taiwan Hiwin Taiwan YYC HERION |

| Deceleration system | Flange reducer | Shimpoo, Japan MOTORE |

| Proportional Valve | SMC | Japan |

| Electrical installation | Schneider | France |

| Tracking sensor system | High precision automatic induction, accuracy 0.1 mm | Shanghai CYPCUT |

| Slag discharge device | Standards | PSL |

| Computer System | Special Industrial PC for laser | Taiwan Yanxiang |

| X-AXIS | servo unit | Fuji/Delta/Yaskawa |

| Y-AXIS | servo unit | Fuji/Delta/Yaskawa |

| Z-AXIS | servo unit | Fuji/Delta/Yaskawa |

| Loading axes | two servo units | BAIGELA |

| Cutting software | Professional CNC cutting software | Shanghai CYPCUT |

| Nesting software | CYPNEST (Optional) | Shanghai FSCUT |

| I / O card | 32 points | FSCUT |

| Voltage Regulator | 30KVA | China |

| Cutting machine | Precision Gantry | PSL |

Main technology parameters,

| Name | CNC Fiber laser cutting machine | |

| laser source | RAYCUS/IPG/MAX | |

| BPP,mm*mrad | 1.27 | |

| Laser wavelength | 1070nm | |

| Maxim cutting speed | 100m/min(according to materials) |

| Max. acceleration | 1.0G |

| Energy instability | ≤2% |

| supported graphic formats | CAD,CorelDraw software,DXF/DWG/PLT |

| cutting area | 3000×1500mm |

| X axis travelling | 3050mm |

| Y axis travelling | 1530mm |

| Z axis travelling | 120mm |

| accuracy of re-position | ±0.03mm/m |

| accuracy of position X/Y axis | ±0.05mm/m |

| Max. loading weight of workbench | 500KG |

| Max. loading weight of Robot | 500KG |

| power of the machine | 350V-420V/50Hz |

| Weight of machine | 3000kg |

| weight of Loading Robot | 1200kg |

| Dimensions | 4500x2300x1600mm |