Product Details

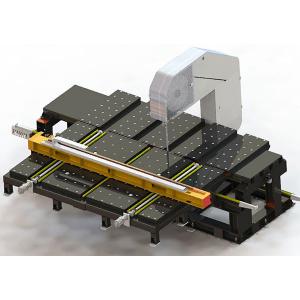

High-speed CNC vertical metal band saw machine sawing Aluminium

plate and bar

Purpose of equipment,

It is mainly used for slitting of aluminum alloy plate and bar.

Main technical parameters,

- Sawing capacity (mm): throat height 600, throat depth 1500,

sawing stroke 4000, feeding stroke 4000

- The saw belt turned 0 degrees

- Diameter of saw wheel (mm): Φ 860 * 2 wheels

- Saw wheel material: duralumin alloy: 7075T651 hard anodizing

- Saw belt material: hard alloy: saw belt (Taiju TCB does not

separate teeth)

- Sizes of saw band (mm): about 7660 length * 41 width * 1.3

thickness *2 / 3 teeth (length shall be subject to the final design)

- Band sawing speed(M / min): 800-2500 (frequency control)

- Band saw motor: Taiwan TACO frequency motor 22KW (6p)

- Main drive system: aluminum alloy pulley + multi wedge belt

(dynamic balance treatment)

- The tension mode of saw belt: independent hydraulic automatic

tension

(belt breaking protection function)

- Feeding mode: saw bow feed

- Feeding slider: Taiwan Hiwin linear 2sets

- Feeding speed (M / min): 0-3000 (servo motor + ball screw + linear

slide)

- Floating material feeding mode: hydraulically driven floating

material roller feeding

- Thickness of incision (mm) ≤ 2

- Cutting slope (mm) ≤ 0.1/500

- Sawing unevenness (mm) ≤ 0.1/500

- Sawing auxiliary machine: cyclone dust collector

- Service life of saw blade ㎡: ≥ 10

Equipment supply scope, (state: B-Buyer, S-Seller)

| No. | Name of part | Design | Supply | Unit | Qty. | Remark |

| 1 | High-speed Vertical Band sawing machine | S | S | set | 1 | |

| 1.1 | Sawing bow | S | S | set | 1 | Precision machining of welding structural parts |

| 1.2 | Driving wheels | S | S | set | 1 | Al. Alloy saw belt wheel |

| 1.3 | Main drive system | S | S | group | 1 | Al.Alloy pulley + multi wedge belt |

| 1.4 | Driven wheel | S | S | group | 1 | Al. alloy saw belt wheel + hydraulic auto tension device |

| 1.5 | Substructure | S | S | group | 1 | Precision machining, welding mechanism |

| 1.6 | Feeding slider | S | S | pc | 2 | Linear guider imported from Taiwan |

| 1.7 | Feeding servo unit | S | S | group | 1 | Delta servo motor + precision planetary reducer |

| 1.8 | Raw material feeding mechanism | S | S | group | 3 | Hydraulic driving |

| 1.9 | Inner & outer machine bed | S | S | group | 2 | Welded structure |

| 1.10 | Saw belt cooling device | S | S | set | 1 | Air pressure oil mist cooling |

| | | | | | |

| 2 | Hydraulic system | S | S | group | 1 | |

| 2.1 | Oil tank | S | S | set | 1 | Made by manufacturer2 |

| 2.2 | Pump station | S | S | group | 1 | Pump: Hitech; Motor: Dongling |

| 2.3 | Temperature control device | S | S | group | 1 | Forced air cooling |

| | | | | | |

| 3 | Pipelines | S | S | | | |

| 3.1 | T.O.P. to the equipment | S | S | group | 1 | Including electricity, compressed air tubes,etc… |

| 3.2 | Internal pipelines | S | S | group | 1 | Preset dust collection pipes |

| | | | | | |

| 4 | Attached spare parts | S | S | | | |

| 4.1 | Sawing band | S | S | band | 2 | Carbide sawing band |

| 4.2 | Cooling oil for Band | S | S | gallon | 2 | |

| | | | | | |

| 5 | Auxiliary equipment | S | S | | | Optional configuration |

| 5.1 | Auto sawdust collection device | S | S | set | 1 | Option |

Company Profile

PSL (Wuhan) has rich experience in design, manufacture and sales

more than 25 years. We are one integration supplier focussed on

Sheet metal processing equipment, Metal pipes of profiles

machining, Lasers application and kinds of automatic production

lines. such as 1) NC/CNC Press Brakes, 2) NC/CNC Shears, 3) Laser

Cutting machine, 4) Laser Welding machine, 5) Rolling machine, 6)

Punching Press, 7) Ironworker, 8) Duct production line, 9)

Cut-to-length production line, 10) Slitting line, 11) Foam Sealing

Spraying machine, and so on.

With high effective communication and quality service in mind, we

strive to bring even better products to our clients through our

continuous effort and a crew dedicated towards improvement.

With customizations from our own in house design, Our machinery are

made efficient and reliable with rigorous testing. We strive to

provide our clients with an pleasant experience with our after-sale

service. PSL will always be the comerstone and partner of your

career.

We are always looking forward to work and grow with you.