Add to Cart

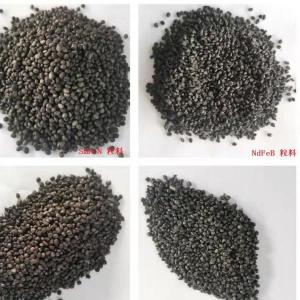

Isotropic Bonded Neodymium Magnet Particles NdFeB Granules Injection NdFeB Compound

Process flow

Application

Feature

| ISO NdFeB/PA12 Compound for Injection 2022.5.8 | |||||||||||||||

| HCNT240L | HCNT240LL | HCNT245LL | HCNT250LL | HCNT250BL | HCNT250L | HCNT255HHL | HCNT2599L | HCNT260L | HCNT260BL | HCNT270L | HCNT280L | ||||

| 单位Unit | |||||||||||||||

| Magnetic Properties | Residual Induction | Br | mT | 400-560 | 410-450 | 460-520 | 470-550 | 470-550 | 470-550 | 480-560 | 510-590 | 510-590 | 510-590 | 560-620 | 600-650 |

| kGs | 4.0-5.6 | 4.1-4.5 | 4.6-5.2 | 4.7-5.5 | 4.7-5.5 | 4.7-5.5 | 4.8-5.6 | 5.1-5.9 | 5.1-5.9 | 5.1-5.9 | 5.6-6.2 | 6.0-6.5 | |||

| Coercive Force | Hcb | kA/m | 183-318 | 247-310 | 310-342 | 310-367 | 310-366 | 310-366 | 334-398 | 334-382 | 334-382 | 334-382 | 358-414 | 366-422 | |

| kOe | 2.3-4.0 | 3.1-3.9 | 3.9-4.3 | 3.9-4.6 | 3.9-4.6 | 3.9-4.6 | 4.2-5.0 | 4.2-4.8 | 4.2-4.8 | 4.2-4.8 | 4.5-5.2 | 4.6-5.3 | |||

| Intrinsic Coercivity | Hcj | kA/m | 270-772 | 573-732 | 597-717 | 636-733 | 636-732 | 637-732 | 1034-1354 | 636-732 | 653-732 | 636-732 | 677-772 | 597-716 | |

| kOe | 3.4-9.7 | 7.2-9.2 | 7.5-9.0 | 8.0-9.2 | 8.0-9.2 | 8.0-9.2 | 13.0-17.0 | 8.0-9.2 | 8.2-9.2 | 8.0-9.2 | 8.5-9.7 | 7.5-9.0 | |||

| Max.BH | (BH)max | kJ/cm3 | 27.8-35.8 | 28-36 | 36.1-41.4 | 39.8-46.2 | 35.8-42.2 | 40-46 | 39.8-51.8 | 43-46 | 46-52 | 46.1-49.5 | 52-60 | 59-68 | |

| MGOe | 3.5-4.5 | 3.5-4.6 | 4.6-5.2 | 5.0-5.8 | 5.3-5.7 | 5.0-5.8 | 5.0-6.5 | 5.5-5.8 | 5.8-6.5 | 5.8-6.2 | 6.5-7.5 | 7.5-8.5 | |||

| Physical Properties | 密度Density | ρ | g/cm3 | 5.2-5.35 | 4.5-4.6 | 4.4-4.6 | 4.9-5.3 | 5.0-5.3 | 4.9-5.3 | 5.0-5.5 | 5.2-5.35 | 4.9-5.3 | 5.15-5.2 | 4.9-5.3 | 5.3-5.6 |

| Melt Flowrate | MFR | g/10min | 300-500 | 300-500 | 120-350 | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 | 450-650 | 300-500 | 450-650 | 300-500 | |

| (270℃ 5kg) | |||||||||||||||

| Shrinkage | % | 0.3-0.5 | 0.9-1.1 | 0.7-1.0 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.1-0.3 | ||

| Tensile Stength | ASTM-D638 | MPa | 47 | 57 | 55 | 46 | 43 | 48 | 44 | 48 | 42 | 46 | 45 | 35 | |

| Flexural Modulus | ASTM-D790 | MPa | 85 | 110 | 105 | 86 | 84 | 84 | 83 | 89 | 85 | 84 | 88 | 65 | |

| Flexural Modulus | ASTM-D790 | Gpa | 15 | 12 | 12 | 14 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 18 | |

| ZOD Impact Strength | ASTM-D256 | (kJ/m2) | 8 | 10 | 11 | 10 | 8.5 | 8 | 8.8 | 8.6 | 8.4 | 8.2 | 8.5 | 6.4 | |

| 射出成型条件 | |||||||||||||||

| LT-35T (35ton ) Ring Φ10xΦ7x10 | Predrying | ℃/hr | 80/4 | ||||||||||||

| Barrel Temp. | T1 (加料) | ℃ | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 250 | 250 | |

| T2 | ℃ | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 270 | 270 | ||

| T3 (料嘴) | ℃ | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 275 | 275 | ||

| Mold Temp. | ℃ | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Pressure | MPa (kg/cm2) | 94 (959) | 82.25 (839) | 105.8 (1079) | 94 (959) | 70.5 (719) | 94.0 (959) | 117.5 (1198) | 94.0 (959) | 94.0 (959) | 94.0 (959) | 105.7 (1079) | 94.0 (959) | ||

| Speed | % | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 80 | 60 | ||

| 1. Molding conditions for customers'reference, the highest temperature of nylon injection barrel is not allowed to exceed 280 degrees. | |||||||||||||||

| 2. It can be customized according to customers'requirements | |||||||||||||||