Add to Cart

We use resistors a lot in most PCB projects, and most of us are

familiar with their function; resistors are one of the most

commonly used components on circuit boards, they are very popular

and fairly easy to use. the flow of current. Therefore, resistors

help to dissipate electrical energy in the form of heat. There are

many types of resistors and they are classified differently and

resistors are usually made of different materials because we use

different materials for different purposes.Another difference in

resistors is the way the wires are drawn out, and in this regard,

the most common type is the axial resistor. Electronics hobbyists,

beginners, and hobbyists generally prefer to use axial resistors

because of their ease of integration into any circuit. There are

rings around each resistor, these rings are color codes that

indicate the resistance value of that particular resistor, and

these rings also tell us the possible tolerance of the resistor.

After the resistor, the capacitor is probably the most common

component on the circuit board, and the capacitor is also the first

choice for PCB enthusiasts. However, we use less capacitors than

resistors. The basic function of a capacitor is to store an

electric charge in it, a capacitor consists of two metal plates

with a dielectric between the two plates, the two plates store

opposite charges, and the dielectric helps to separate them. In

this way, current begins to flow through the circuit.Capacitors are

classified in several ways. However, we mainly classify capacitors

according to their dielectric material. This is because the

dielectric material is responsible for giving the capacitor key

properties; the denser the dielectric material, the more charge the

capacitor can store on its plates; that's why we tend to use

premium materials to make capacitors for taller capacitors. A

typical capacitor has two wires extending from a metal plate. We

use these wires to integrate capacitors into circuits.

| Parameter | Value |

|---|---|

| Min. Line Width | 0.075mm |

| Type | PCB Electronic Components |

| Layer | 1-20 Layers |

| Min. Hole Size | 0.2mm |

| Surface Finish | HASL, ENIG, OSP, Etc. |

| Packaging | Vacuum Package, Tray Package, Etc. |

| Lead Time | 2-4 Weeks |

| Application | Industrial, Automotive, Medical, Etc. |

| Min. Line Spacing | 0.075mm |

| Board Thickness | 0.2-3.2mm |

| Integrated Circuit Assemblies | Yes |

| Circuitry Boards Components | Yes |

| Electronic Components Assemblies | Yes |

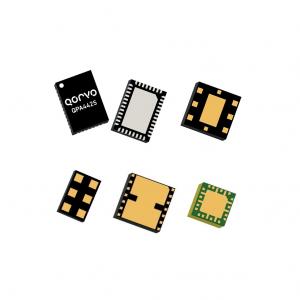

PCB Electronic Components offered by Cesgate are specifically

designed for industrial, automotive, medical, and other

applications. All of our components are UL, IATF16949, ISO9001, and

ISO14001 certified. With no minimum order quantity, these

components are available at a price of just $1.00 per piece. We

offer both vacuum packing and ESD + packing for our PCBs and PCBA

components. We offer a quick turnaround time of 3-7 working days

for delivery. Our payment terms include T/T and L/C, and we have a

daily supply capacity of 13kk soldering spots. Our silkscreen

colors are available in white, black, yellow, and more. We also

offer a minimum hole size of 0.2mm. Our components are available

with both vacuum and tray packaging. Lead times are typically 2-4

weeks.

Our PCB Electronic Components are perfect for any reliable

circuitry board assembly. With a wide range of components

available, Cesgate is your go-to source for all of your circuit

board and circuitry board component needs. We provide quality

components for any kind of electronic device, from consumer

electronics to military grade equipment. Our components are

designed to provide optimal performance and reliability in even the

most demanding applications. Whether you need a single component or

an entire set of components, Cesgate has the perfect solution for

you.

We provide dedicated technical support and services for all PCB

electronic components. Our team of experienced and knowledgeable

engineers is available to assist with product selection, design,

installation, and troubleshooting.

We provide a wide range of services, including:

We strive to provide the highest quality of service, and are

committed to ensuring customer satisfaction. Contact us today for

all your PCB electronic component needs.

Q1: What is PCB Prototype Service?

A1: PCB Prototype Service is a Cesgate service that specializes in

the development and manufacture of Printed Circuit Boards (PCBs)

for a wide range of electronics applications. The service offers a

quick turnaround time and high quality products that can be

tailored to customer specifications.

Q2: How can we guarantee quality?

A2: CESGATE: Always a pre-production sample before mass

production;Always final Inspection and test report before shipment;

Q3: What is the minimum order quantity for PCB Prototype Service?

A3: There is no minimum order quantity required for PCB Prototype

Service.

Q4: What is the difference between the HDI board and the general

circuit board?

A4: Most of HDI use laser to form holes, while general circuit

boards only use mechanical drilling, and HDI boards are

manufactured by the build-up method (Build Up), so more layers will

be added, while general circuit boards are only added once.

Q5: What are the common substrates of CESGATE?

A5:Tg-140: ISOLA FR402 / NAN-YA NP-140

Tg-150: ISOLA IS400 / NAN-YA NP-155

Tg-170~180: ISOLA 370HR / NPN-YA / NAN-YA NP-175F