Add to Cart

►Our PET strap extrusion line is a professional PET strap making machine that can manufacture PET straps with a production capacity of 400-4500KG/H. It is equipped with an oil removal and dust removal filter, a pre-drying tower with 5000L capacity, and a host inverter of 75KW (INVT). The line speed is adjustable between 220-260m/min, making it an ideal PET strap production line for PET strap manufacturing equipment.

►Our PET strap extrusion machinery uses advanced technology to ensure that the straps produced are of consistent quality. The materials used are eco-friendly and all the parts used are of the highest quality. With easy operation and maintenance, our PET strap extrusion line is the perfect choice for those looking for a reliable and cost-effective PET strap production line.

►PET belt, also known as plastic steel belt, is a new type of binding belt that is currently popular in the world to replace steel belts, and is widely used in steel, aluminum, chemical fiber, cotton spinning, tobacco, paper industry, metal canning and other industries.

►Strong tensile strength: not only the tensile strength of steel strip, but also the ductility of impact resistance, which can ensure the transportation safety of your products.

►Small elongation: the elongation is only one-sixth of the polypropylene (PP) belt, which can maintain the tension for a long time.

►Strong temperature resistance: melting point is 260 degrees, 120 degrees below the use without deformation.

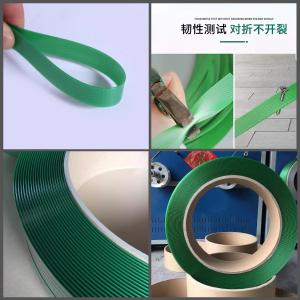

►Good flexibility: no sharp edge of steel belt, safe operation, neither hurt hands nor damage to the bound object.

►Beautiful without rust: no steel belt rust pollution to the bundled object, bright color can be seen.

►Good economic benefits: the length of 1 ton of plastic steel belt is equivalent to 6 tons of steel belt, and the unit price per meter is lower than that of steel belt, which can reduce costs for you.

| Parameter | Value |

|---|---|

| Name | PET plastic steel belt production equipment |

Applicable raw materials | PET bottle flake material, 100% broken material |

| Width | 9-32mm |

| Strap Thickness | 0.6-1.2mm |

| Number of tapes | 4 |

| Main motor | 75KW (Siemens) |

Host inverter | 75KW (INVT) |

| Winder | Manual/automatic |

Screw | ç130mm |

Winder | 4sets |

| Neat winding | YES |

One discharging four die heads4 | 1set |

| Advanced technology | YES |

| Metering pump | 100CC |

| Strong and durable | YES |

| Honeycomb rotary dehumidification dryer | 0ST-2000 |

Metering pump | 100CC |

The PET Strap Extrusion Line has been manufactured by JIATUO CHINA with Model Number: JTPET. It is certified with CE SGS ISO and the Minimum Order Quantity is 1 SET. The Delivery Time is 50-60 days. With the Strap Width of 9-32mm and Strap Thickness of 0.6-1.2mm, it is mainly used for PET-130 material. The Paper core specification is ¢ 406*150mm and the Extrusion Capacity is 400-4500KG/H.

The PET Strap Extrusion Line is widely used for PET Strap Manufacturing Line and PET Strap Production Line. It is the perfect choice for customers who need a stable and efficient PET Strap Extrusion Machinery. It can meet the different needs of customers, from small to large production, with high quality and high efficiency.

The PET Strap Extrusion Machinery of JIATUO CHINA is characterized by its excellent performance in terms of speed and accuracy. It is capable of producing PET straps with superior quality and strength, and is designed to be both cost-effective and reliable. It also comes with a comprehensive after-sales service and technical support to ensure complete customer satisfaction.

Brand Name: JIATUO CHINA

Model Number: JTPET

Place of Origin: CHINA

Certification: CE SGS ISO

Minimum Order Quantity: 1 SET

Delivery Time: 50-60 Days

Honeycomb rotary dehumidification dryer: 0ST-2000

Neat winding: YES

Equipment footprint: 60*2.0*7.0M

Number of tapes: 4

30 years old brand: YES

Are you looking for a reliable PET Strap Extrusion Line manufacturer? JIATUO CHINA is your answer. Our JTPET PET Strap Extrusion Line is renowned for its quality and performance. It comes with CE SGS ISO certification and is available for a minimum quantity of 1 SET. The delivery time for our PET Strap Extrusion Line is 50-60 Days. We also provide Honeycomb rotary dehumidification dryer 0ST-2000, neat winding, an equipment footprint of 60*2.0*7.0M, 4 tapes, and a 30 years old brand.

PET Strap Extrusion Line Technical Support and Service

We provide comprehensive technical support and service for PET Strap Extrusion Line. Our team of experienced engineers can help you achieve the best performance from your line so that you can meet your production requirements.

We offer on-site installation, commissioning and training for all our machines. Our experienced engineers will provide you with detailed instructions on how to use your equipment safely and correctly.

We also provide regular maintenance and repair services to ensure your line is running properly and efficiently. We can also provide spare parts and consumables to help keep your line running.

We are committed to providing the highest quality technical support and service for our customers. Our team of engineers and customer service representatives are available 24/7 to answer any questions or concerns you may have.

The PET Strap Extrusion Line is shipped in a wooden crate with a custom-made foam insert for added protection during transit. The crate is securely strapped and sealed, and the entire package is labeled with the correct shipping information.

Once the package is ready for shipment, it is loaded onto a truck for transport to its destination. The package is monitored and tracked throughout its entire journey to ensure it arrives in perfect condition.