Add to Cart

1. The production of plastic raw materials can be recycled materials or mixed new materials to produce packaging belts, and calcium carbonate can also be added appropriately according to customer conditions to reduce production costs, improve product profits, and break through market competitiveness.

2. The production of various specifications of the pole packing belt can be applied to all kinds of automatic unmanned balers at home and abroad.

3. High output, finished product line speed up to 280-310m/min.

4. High precision and high quality screw, famous brand, unique parameter design, with large extrusion capacity, good plasticization, high hardness, wear resistance and other advantages.

5. Foreign quality CNC machine tool cutting, high-precision die parts, so that the product molding quality is stable, thickness error range is less than the national packaging belt acceptance standards.

6. Unique five-roll traction system, stable traction, stable operation of equipment, reduce the failure rate, reduce the maintenance cost of more than 80%.

7. Unique cooling circulation system, multiple sets of shaped guide rail, so that the packaging belt cooling contraction better shape, more accurate size, internal reciprocating winding, full use of heat energy, efficient reduction of power loss. High strength alloy steel wheel, shaft, gear, etc., after carburizing, quenching, grinding and other processes, wear-resistant, durable, effectively reduce the failure rate of equipment.

8. High precision embossing wheel, clear embossing, adjustable pressure, make the packing belt more beautiful.

9. Hengli winding system, unique design of correction device, winding neat, smooth and beautiful surface.

10. It is equipped with non-stop automatic net changer, which can change the net without stopping and maximize the benefit.

.| Product Name | PP Strap Making Machine |

|---|---|

Width | 5-19mm |

Thickness | 0.6-1.2mm |

Paper core diameter | Ø200*180mm |

| Trademark | JiaTuo China |

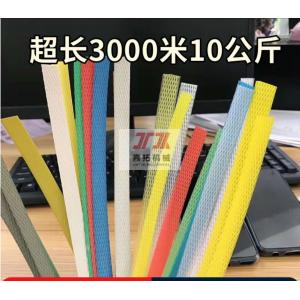

| Strap Color | By Customer's Requirement |

| Strap Material | PP Recycle Material/New Raw Material |

| Screw Material | 38CrMoALA |

| Automatic Grade | Fully Automatic |

| Extruder | Single Or Double Screw |

| Strap Speed | >280m/min |

| Applicable Raw Materials | Recycled Material And Polypropylene |

| Application | PP Strap Making Machine |

Winding method | manual/automatic |

| Key Words | Plastic Strap Production Machine, Plastic Strap Manufacture Equipment, Polypropylene Strap Making Machine |

PP strap making machine, also known as polypropylene banding machine, is a specialized manufacturing machine used for producing plastic straps. It is designed to cater to the needs of various industries, such as packaging, logistics, and transportation, where strapping is a crucial process for securing and bundling goods and products.

The model number of this machine is JTPP-110 and it is manufactured in China. It has received the prestigious ISO certification, ensuring its quality and reliability. The minimum order quantity is 1 set and the price is negotiable, making it accessible to businesses of all sizes. The packaging details include plastic film, providing protection during transportation.

The delivery time for the PP strap making machine is 30-40 days, which is relatively quick compared to other machines in the market. It is a fully automatic machine, which means it requires minimal human intervention, making the production process more efficient and less time-consuming.

One of the key features of this machine is its high speed. It is capable of producing plastic straps at a rapid pace, meeting the demands of industries that require bulk production. This makes it a popular choice for businesses that need a quick and efficient solution for their strapping needs.

Moreover, the PP strap making machine is designed to be user-friendly and easy to operate. It comes with a warranty of 1 year, ensuring its longevity and providing peace of mind to the buyers. The screw material used in this machine is 38CrMoALA, known for its strength and durability, ensuring the longevity of the machine.

This machine is suitable for a wide range of raw materials, including recycled material and polypropylene. This makes it an environmentally friendly option, as it can utilize recycled materials for production, reducing waste and promoting sustainability.

In conclusion, the PP strap making machine is a highly efficient, high-speed, and user-friendly machine, suitable for various industries. With its fully automatic operation, quick delivery time, and compatibility with different raw materials, it is a cost-effective solution for businesses looking for a plastic strap production machine.

Our PP Strap Making Machine is carefully packaged and shipped to ensure its safe arrival at your designated location.

The machine is first wrapped in a layer of protective film to prevent any scratches or damage during transportation.

Next, it is placed in a sturdy wooden crate and securely fastened to prevent any movement or shifting during transit.

Additional padding and cushioning materials are also used to provide extra protection against any potential impacts.

The crate is then sealed and labeled with detailed handling instructions and product information for easy identification.

We offer both air and sea freight options for shipping our PP Strap Making Machine.

For air freight, we work with trusted and reliable carriers to ensure prompt and timely delivery to your location.

For sea freight, our team carefully plans and coordinates the shipment to ensure the most cost-effective and efficient route is taken.

We also provide all necessary documentation for customs clearance and tracking information for easy monitoring of your shipment.

With our careful packaging and efficient shipping methods, you can rest assured that your PP Strap Making Machine will arrive in excellent condition and on time.