Product Details

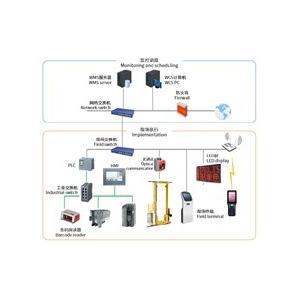

ASRS WMS WCS Warehouse Control System Software Management Control

WCS Warehouse Control System Software System ASRS Material Handling

System

WCS is one management control system between WMS and PLC. It can

coordinate the operation of various logistics equipment, such as

conveyor, stacker, shuttle, robot, guided vehicles, and others.

Mainly realize the integration, unified scheduling and monitoring

of various interfaces.

- Automatically allocate and execute storage and sorting tasks of WMS

- Real-time monitoring of equipment

- Read and set PLC parameters

- Manual control of slackers and conveyors

- Record equipment running tasks and fault logs

WCS System Features

|

| Real-time monitoring | Support global screen display. Support partial magnification display. Support real-time dynamic picture. Stop status, running status, fault status, disabled status, etc.

are displayed in different colors or animations. |

| Parameter setting | Read the current parameters of the device from the PLC. Provides a parameter setting interface. Write the modified device parameters to the PLC. Support parameter initialization function. |

| Manual control | Provides control functions such as start-stop, sealing, resetting,

data clearing, and initialization of conveyor line equipment. |

| Task management (background) | Read barcode information from PLC. Send barcode information and device number to WMS, and receive

direction information returned by WMS. Send task instructions (including route information) to PLC. Read the return value of the PLC task command to determine whether

the command is completed. If the return value of the task command is not read before the new

barcode is read, the task is recorded as incomplete; the incomplete

task does not affect the sending of subsequent task commands. |

| System log | Task log: including device number, task serial number, barcode

information, route information, execution result, task initiation

time, task completion time, etc. System fault log: including equipment type, fault code, fault

description, fault level, fault occurrence time and other

information. Operation log (manual control): including control instructions,

equipment codes, execution results, instruction issuing time,

instruction completion time, and operator. |

Company Profile

KINTE provides systematic solutions for the intelligent logistics system by scientific research &

development and technological standard innovation, forming three

main business sectors of Quality and Technical Services,

Intelligent Equipment, Environmental Protection Coatings and Resin.

Serving more than 10,000 customers annually, covering more than 30

countries and regions around the world, it has become an active

practitioner of “the Belt and Road” initiative.

KINTE has undertaken a large number of national, provincial and

municipal knotty-problem-tackling scientific research projects.

From 1998 to 2021, over 600 scientific and technological

achievements were made, including over 380 outstanding scientific

and technological achievements, of which there are 9 national

achievement awards, 146 provincial and ministerial achievement

awards, and 63 municipal achievement awards. Over 100 national

patents have been awarded , with the transformation rate of

scientific and technological achievements reaching up to 85%.

KINTE has won the national technological market “Golden Bridge

Award” for five times in 10 consecutive years, which holds every

two years. Besides, Kinte owns multiple certificates, such as

“Certificate for Foreign Engineering Contract of the People’s

Republic of China” issued by the Ministry of Commerce of the

People’s Republic of China (the only company with this certificate

in Chinese household electrical appliance industry), “Engineering

Design Certificate (Class A)” issued by the Ministry of Housing and

Urban-Rural Development of the People’s Republic of China and

“Special Engineering Design Qualification Certificate” issued by

the Ministry of Environmental Protection of the People’s Republic

of China.

Powerful Basic Strength

Strong Scientific Research Capacity

Extensive Engineering Experience

Perfect Service System

- A wholly owned subsidiary of SINOMACH (a central government

governed enterprise, ranked 250th among World Top 500).

- Enterprise with bank credit of AAA level.

- 14 wholly owned or holding industrial subsidiaries.

- Completed more than 300 turnkey projects.

- Customers from more than 30 countries and regions.

- Holding the “Certificate for Foreign Engineering Contract of the

People’s Republic of China”.

- Internationally : We set agency and after-sales service points in

countries such as India, Saudi Arabia, Iran, Egypt, Turkey, Brazil,

Algeria, Pakistan, etc..

- Marketing center: Offer 24-hours hotline and email service.

- Dedicated after-sales service department.