Add to Cart

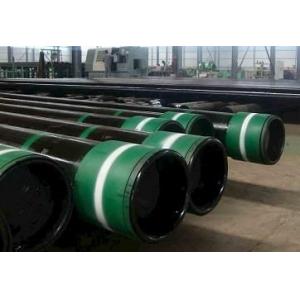

Drilling Casing Pipe J55 API 5CT 4 1/2" To 20" New Oilfield Equipment

API 5CT Casing Pipe

Grade: H40, J55, K55, L80, L80-13Cr, L80-9Cr, N80-1, N80Q, P110

O.D: 4 1/2"-20"

Length: R1, R2, R3

Connection: STC, LTC, BTC, Premium Connection (NEW , PH-6)

Casing Pipe Data Table

| Labels a | OD mm | Nominal Linear Mass b,c T&C kg/m | WT t mm | Type of end-finish d | |||||||||

| H40 | J55 K55 | M65 | L80 R95 | N80 Type 1, Q | C90 T95 | P110 | Q125 | ||||||

| 1 | 2 | ||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114.30 114.30 114.30 114.30 114.30 | 14.14 15.63 17.26 20.09 22.47 | 5.21 5.69 6.35 7.37 8.56 | PS - - - - | PS PSB PSLB - - | PS PSB PLB PLB - | - - PLB PLB - | - - PLB PLB - | - - PLB PLB - | - - PLB PLB PLB | - - - - PLB | |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127.00 127.00 127.00 127.00 127.00 127.00 127.00 | 17.11 19.35 22.32 26.79 31.85 34.53 35.86 | 5.59 6.43 7.52 9.19 11.10 12.14 12.70 | - - - - - - - | PS PSLB PSLBE - - - - | PS PSLB PLB PLB PLB - - | - - PLB PLB PLB PLB PLB | - - PLB PLB PLB PLB PLB | - - PLB PLB PLB PLB PLB | - - PLB PLB PLB PLB PLB | - - - PLB PLB PLB PLB | |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 | 20.83 23.07 25.30 29.76 34.23 39.88 44.20 48.51 52.53 56.55 60.27 61.14 | 6.20 6.98 7.72 9.17 10.54 12.70 14.27 15.88 17.45 19.05 20.62 22.22 | PS - - - - - - - - - - - | PS PSLBE PSLBE - - - - - - - - - | PS PSLB PLB PLB PLB - - - - - - - | - - PLBE PLBE PLBE - - - - - - - | - - PLBE PLBE PLBE - - - - - - - | - - PLBE PLBE PLBE P P P P P P P | - - PLBE PLBE PLBE - - - - - - - | - - - - PLBE - - - - - - - | |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168.28 168.28 168.28 168.28 | 29.76 35.72 41.67 47.62 | 7.32 8.94 10.59 12.06 | PS - - - | PSLB PSLBE - - | PSLB PLB PLB - | - PLBE PLBE PLBE | - PLBE PLBE PLBE | - PLBE PLBE PLBE | - PLBE PLBE PLBE | - - - PLBE | |

| 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 | 177.80 177.80 177.80 177.80 177.80 177.80 177.80 | 25.30 29.76 34.23 38.69 43.16 47.62 52.09 | 5.87 6.91 8.05 9.19 10.36 11.51 12.65 | PS PS - - - - - | - PS PSLBE PSLBE - - - | - PS PLB PLB PLB PLB - | - - PLB PLB PLB PLB PLB | - - PLB PLB PLB PLB PLB | - - PLB PLB PLB PLB PLB | - - - PLB PLB PLB PLBE | - - - - - - PLB | |

| 7 7 7 7 7 7 | 38.00 42.70 46.40 50.10 53.60 57.10 | 177.80 177.80 177.80 177.80 177.80 177.80 | 56.55 63.54 69.05 74.56 79.77 84.97 | 13.72 15.88 17.45 19.05 20.62 22.22 | - - - - - - | - - - - - - | - - - - - - | PLB - - - - - | PLB - - - - - | PLB P P P P P | PLB - - - - - | PLB - - - - - | |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 | 35.72 39.29 44.20 50.15 58.04 63.69 67.41 70.09 76.19 82.30 | 7.62 8.33 9.52 10.92 12.70 14.27 15.11 15.88 17.45 19.05 | PS - - - - - - - - - | - PSLB - - - - - - - - | - PSLB PLB PLB - - - - - - | - PLB PLB PLB PLB PLB PLB PLB - - | - PLB PLB PLB PLB PLB PLB PLB - - | - PLB PLB PLB PLB PLB PLB PLB P P | - - PLB PLB PLB PLB PLB PLB - - | - - - - PLB PLB PLB PLB - - | |

| 7-3/4 | 46.10 | 196.85 | 68.60 | 15.11 | - | - | - | P | P | P | P | P | |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219.08 219.08 219.08 219.08 219.08 219.08 219.08 | 35.72 41.67 47.62 53.57 59.53 65.48 72.92 | 6.71 7.72 8.94 10.16 11.43 12.70 14.15 | - PS PS - - - - | PS PS - PSLB PSLB PLB - | PS PS PSLB PSLB PLB - - | - - - PLB PLB PLB PLB | - - - PLB PLB PLB PLBE | - - - PLBE PLBE PLBE PLBE | - - - PLB PLB PLB | - - - - - PLB | |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 | 48.07 53.57 59.53 64.73 69.94 79.62 86.91 88.40 96.58 104.62 112.50 | 7.92 8.94 10.03 11.05 11.99 13.84 15.11 15.47 17.07 18.64 20.24 | PS PS - - - - - - - - - | - PSLB PSLB - - - - - | - PSLB PSLB PLB PLB - - - - - | - - PLB PLB PLB PLB PLB - - - - | - - PLB PLB PLB PLB PLB - - - | - - PLB PLB PLB PLB PLB P P P P | - - - PLB PLB PLB PLB - - - - | - - - - PLB PLB PLB - - - - | |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 | 48.74 60.27 67.71 75.90 82.59 90.33 97.77 108.93 117.86 126.94 | 7.09 8.89 10.16 11.43 12.57 13.84 15.11 17.07 18.64 20.24 | PS PS - - - - - - - - | - PSB PSB PSB - - - - - - | - PSB PSB PSB PSB - - - - - | - - - PSB PSB - - - - - | - - - PSB PSB - - - - - | - - - PSB PSB PSB PSB P P P | - - - PSB PSB PSB PSB - - - | - - - - - PSB PSB - - - | |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298.45 298.45 298.45 298.45 298.45 298.45 | 62.50 69.94 80.36 89.29 96.73 105.66 | 8.46 9.53 11.05 12.42 13.56 14.78 | PS - - - - - | - PSB PSB PSB - - | - PSB PSB PSB - - | - - - PSB P P | - - - PSB P P | - - - PSB P P | - - - PSB P P | - - - PSB P P | |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339.72 339.72 339.72 339.72 339.72 | 71.43 81.10 90.78 101.19 107.15 | 8.38 9.65 10.92 12.19 13.06 | PS - - - - | - PSB PSB PSB - | - PSB PSB PSB - | - - - PSB PSB | - - - PSB PSB | - - - PSB PSB | - - - PSB PSB | - - - - PSB | |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406.40 406.40 406.40 406.40 | 96.73 111.61 125.01 162.21 | 9.53 11.13 12.57 16.66 | PS - - - | - PSB PSB P | - PSB PSB - | - - - P | - - - P | - - - - | - - - P | - - - P | |

| 18-5/8 | 87.50 | 473.08 | 130.21 | 11.05 | PS | PSB | PSB | - | - | - | - | - | |

| 20 20 20 | 94.00 106.50 133.00 | 508.00 508.00 508.00 | 139.89 158.49 197.93 | 11.13 12.70 16.13 | PSL - - | PSLB PSLB PSLB | PSLB PSLB - | - - - | - - - | - - - | - - - | - - - | |

| P=Plain end; S=short round thread; L=Long round thread; B--Buttress thread; | |||||||||||||

a: Labels are for information and assistance in ordering. b: Nominal linear masses (col. 4) are shown for information only. c: The densities of martensitic chromium steels (L80 Types 9Cr and 13Cr) are different from carbon steels. The masses shown are therefore not accurate for martensitic chromium steels. A mass correction factor of 0.989 may be used. d: Buttress casing i s available with regualr, special clearance coupings or special clearance couplings with special bevel. | |||||||||||||

API 5CT MATERIALS CHEMICAL COMPOSITION

| Group | Grade | Type | C | Mn | Mo | Cr | Ni max | Cu max | P max | S max | Si max | ||||

| min | max | min | max | min | max | min | max | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – |

| J55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| K55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| N80 | 1 | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| N80 | Q | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| R95 | – | – | 0.45 c | – | 1.9 | – | – | – | – | – | – | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – |

| L80 | 1 | – | 0.43 a | – | 1.9 | – | – | – | – | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | – | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | – | – | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | – | 0.35 | – | 1.2 | 0.25 b | 0.85 | – | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| T95 | 1 | – | 0.35 | – | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| C110 | – | – | 0.35 | – | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | – | 0.02 | 0.005 | – | |

| 3 | P110 | e | – | – | – | – | – | – | – | – | – | – | 0.030 e | 0.030 e | – |

| 4 | Q125 | 1 | – | 0.35 | 1.35 | – | 0.85 | – | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| a The carbon content for L80 may be increased up to 0.50 % maximum

if the product is oil-quenched. b The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the wall thickness is less than 17.78 mm. c The carbon content for R95 may be increased up to 0.55 % maximum if the product is oil-quenched. d The molybdenum content for T95 Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 17.78 mm. e For EW Grade P110, the phosphorus content shall be 0.020 % maximum and the sulfur content 0.010 % maximum. NL = no limit. Elements shown shall be reported in product analysis. | |||||||||||||||

CASING PIPE MATERIALS – MECHANICAL PROPERTIES

| Group | Grade | Type | Total elongation under load % | Yield strength MPa | Tensile strength min. MPa | Hardness a max. | Specified wall thickness mm | Allowable hardness variation b HRC | ||

| min | max | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | – | 0.5 | 276 | 552 | 414 | – | – | – | – |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | – | – | |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | – | – | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | – | – | |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | – | – | |

| R95 | – | 0.5 | 655 | 758 | 724 | – | – | – | – | |

| 2 | M65 | – | 0.5 | 448 | 586 | 586 | 22 | 235 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | – | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 to 19.0 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | – | 0.6 | 758 | 965 | 862 | – | – | – | – |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | – | ≤ 12.70 12.71 to 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| a In case of dispute, laboratory Rockwell C hardness testing shall

be used as the referee method. b No hardness limits are specified, but the maximum variation is restricted as a manufacturing control in accordance with 7.8 and 7.9 of API Spec. 5CT. | ||||||||||