Add to Cart

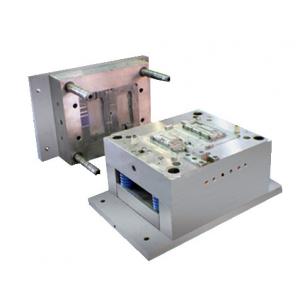

Mold Injection Molding ABS Injection Mold Electric Car Toy No Heating

Product Description

| Product Material | PP/PVC/PE/HDPE/TPU/PMMA/TPU/NYLON6/NYLON66 |

| Mould material | P20/H718/S136 |

| Mould life | 500,000 shots |

| Software | CAD/IGS /STEP/STP /PDF |

| Package | Wooden case |

| Gate type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mould time | 40 days for first time testing sample |

| Injection time | 3-5 days after confirmation of the sample |

| Shipping time | 18-30 days sea shipment |

| Payment terms | 50% advanced payment before mould making, balance after sample confirmed. |

Products Description:

| Flame retardant rating | UL94V-0 | Other Material | Nylon PA66, PA6T, PA9T with glass fiber LCP, PBT, POM, etc. |

| Color | Black | Other standard | Halogen-free Compliant |

| RoHS Compliant | Yes | Lead time | 7~15 days |

| MOQ | 100~500 PCS per lot | Advantages | 1, Both have vertical and horizontal type injection machines. 2, Offering one-stop fabrication services from mold design, manufacture, assembly, and delivery. 3, Short delivery time, but quick response. 4, Professional in various material. 5, Strong R&D support, and quality assurance. |

How Does Plastic Injection Mould Work?

The manufacturing process for molded parts is complex. Before your

parts are even molded, we're there to help you with comprehensive

manufacturability feedback and consultative design services, so you

can avoid mold design pitfalls before the resin hits the mold. From

there, our production process is documented and optimized using

scientific molding so you get high-quality parts consistently and

reliably with every production run.

Critical-to-quality (CTQ) dimensions you call out on models let us know what areas are most crucial to the success of your parts. Once the parts start molding, the process and samples are qualified using automated inline CMM technology, generating a detailed FAI and process capability study with no additional lead time.

Our thermoplastic injection molding is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. As part of the scientific molding process, our molders independently optimize and monitor fill speed, hold pressure, and hold time, and periodically inspect part quality and cosmetics. During the molding process, we use an automated inline CMM to ensure dimensional accuracy, as well as generate a detailed process capability study and FAI report.

Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

It’s vital to evaluate how a ABS Injection Mold will align with your project needs. A part used in a medical or military application as compared with a toy or food container, for example, demands the attention and expertise of ABS Injection Mold that are truly experienced in specialized complex design, engineering and support. Plastic components used in such applications must adhere to strict specifications and compliance requirements.

Some ABS Injection Mold claim to provide custom services, but the industry lacks a clear definition of what “custom” really means — resulting in some manufacturers contracting with molders that are woefully unqualified to accurately produce highly specialized designs. Just because a molder can facilitate development of an original tool doesn’t constitute a truly custom service (or ensure a desirable outcome). Many of these molders are limited to producing simplistic designs and lack the ability to engineer complex plastic parts with precise specifications and tight tolerances.

Professional manufacturer Custom Plastic Parts, Injection Plastic Product

1. Professional manufacturer/Service

2. Waterproof&Scratch-off

3. Various shape, design and size as customer require

4. Certification: ISO9001, SGS, CTI, ROHS

5.Manufacturer: over 20 years production experience

6.Low Price, High quality, Durable, Fast Delivery

FAQ

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees

about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for

you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then

mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for

inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know

which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.