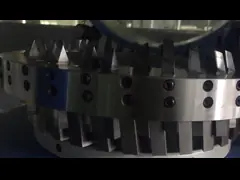

Turning Cubic Boron Nitride Tool Inserts thermal stability Customized

Add to Cart

Cubic Boron Nitride Tool For Turning

Cubic Boron Nitride Tool Material

The second superhard material, cubic boron nitride (CBN),

synthesized by a method similar to the diamond manufacturing

method, is second only to diamond in terms of hardness and thermal

conductivity, and has excellent thermal stability. It can also be

heated to 10000C in the atmosphere. Oxidation does not occur. CBN

has extremely stable chemical properties for ferrous metals and can

be widely used in the processing of steel products.

(1) Types of cubic boron nitride tools

Cubic boron nitride (CBN) is a substance that does not exist in

nature, and can be divided into single crystal and polycrystalline,

namely CBN single crystal and polycrystalline cubic boron nitride

(Polycrystalline cubic bornnitride, referred to as PCBN). CBN is

one of the allotropes of boron nitride (BN) with a structure

similar to diamond.

PCBN (polycrystalline cubic boron nitride) is a polycrystalline

material that sinters fine CBN materials together through bonding

phases (TiC, TiN, Al, Ti, etc.) under high temperature and high

pressure. Diamond tool material, it and diamond are collectively

referred to as superhard tool material. PCBN is mainly used to make

knives or other tools.

PCBN tools can be divided into integral PCBN inserts and PCBN

composite inserts sintered with cemented carbide.

PCBN composite inserts are made by sintering a layer of PCBN with a

thickness of 0.5 to 1.0 mm on cemented carbide with good strength

and toughness. Its properties have good toughness, high hardness

and wear resistance. It solves the problems of low bending strength

and difficult welding of CBN inserts.

⑵ The main properties and characteristics of cubic boron nitride

Although the hardness of cubic boron nitride is slightly lower than

that of diamond, it is much higher than other high hardness

materials. The outstanding advantage of CBN is that the thermal

stability is much higher than that of diamond, which can reach

above 1200°C (diamond is 700-800°C). reaction. The main performance

characteristics of cubic boron nitride are as follows.

① High hardness and wear resistance: CBN crystal structure is

similar to diamond, with hardness and strength similar to diamond.

PCBN is especially suitable for processing high hardness materials

that can only be ground before, and can obtain better surface

quality of workpiece.

② It has high thermal stability: the heat resistance of CBN can

reach 1400~1500℃, which is almost l times higher than that of

diamond (700~800℃). PCBN tools can be used for high-speed cutting

of superalloys and hardened steels at a speed 3 to 5 times higher

than that of carbide tools.

③ Excellent chemical stability: it does not have a chemical effect

with iron-based materials at 1200-1300 ° C, and will not wear as

sharply as diamond. At this time, it can still maintain the

hardness of cemented carbide; PCBN tools are suitable for cutting

hardened steel. Parts and chilled cast iron, can be widely used in

high-speed cutting of cast iron.

④ It has good thermal conductivity: Although the thermal

conductivity of CBN is not as good as that of diamond, the thermal

conductivity of PCBN is second only to diamond among various tool

materials, and is much higher than that of high-speed steel and

cemented carbide.

⑤ Has a lower coefficient of friction: a low coefficient of

friction can reduce the cutting force during cutting, reduce the

cutting temperature, and improve the quality of the machined

surface.

(3) Application of cubic boron nitride tool

Cubic boron nitride is suitable for finishing all kinds of hardened

steel, hard cast iron, superalloy, cemented carbide, surface

sprayed materials and other difficult-to-cut materials. The

machining accuracy can reach IT5 (the hole is IT6), and the surface

roughness value can be as small as Ra1.25~0.20μm.

CBN tool material has poor toughness and flexural strength.

Therefore, cubic boron nitride turning tools are not suitable for

rough machining at low speed and large impact load; at the same

time, it is not suitable for cutting materials with high plasticity

(such as aluminum alloys, copper alloys, nickel-based alloys,

steels with high plasticity, etc.), because cutting these Severe

built-up edge occurs when metal is used, which deteriorates the

machined surface.

| parameter table of PCBN machining material PCBN | ||||||||||||||||

| PCD grade Machining material | KB10 | KB55 | KB11 | KB30 | KB50 | KB21 | KB65 | KB70 | KB90 | KB91 | KB95T | CUTTING SPPED(m/min) | feeding rate(mm/rev) | cutting depth(mm) | ||

| 2μ | 1-2μ | 2μ | 2μ | 2μ | 2μ | 3μ | 15μ | 10μ | 2-4μ | 1-2μ | ||||||

| chilled steel | Ο | Ο | Ο | ▄ | 60-200 | 0.1-0.3 | >3.0 | |||||||||

| Ο | ▄ | 100-250 | 0.025-0.5 | 0.05-0.3 | ||||||||||||

| grey castiron | ▄ | 400-2500 | 0.1-0.8 | >3.0 | ||||||||||||

| ▄ | 700-2000 | 0.5-2.0 | 2.0-5.0 | |||||||||||||

| hard iron | ▄ | 40-150 | 0.1-1.0 | >5.0 | ||||||||||||

| powder metallurgy | Ο | ▄ | Ο | Ο | 70-250 | 0.025-0.2 | 0.05-0.2 | |||||||||

| hard facing alloys | ▄ | 230-500 | 0.1-0.3 | 0.2-2.0 | ||||||||||||

| cutter/die steel | Ο | Ο | Ο | Ο | ▄ | 600-150 | 0.15-0.6 | 0.1-2.5 | ||||||||

| 90-110 | 0.1-0.2 | 0.1-0.5 | ||||||||||||||

| chilled steel(>45HRC) | Ο | Ο | Ο | ▄ | 90-120 | 0.1-0.2 | 0.1-1.0 | |||||||||

| 65-120 | 0.1-0.5 | 0.5-2.5 | ||||||||||||||

| pearlite gray cast iron | 100-150 | 0.1-0.2 | 0.1-0.5 | |||||||||||||

| 200-400 | 0.1-0.2 | 0.1-1.0 | ||||||||||||||

| hard cast iron(>45HRC) | Ο | Ο | ▄ | 40-100 | 0.1-0.6 | 0.1-2.5 | ||||||||||