Gear Shaping Slotting Milling Cutter Grey Finishing High Precision

Brand Name:AOJIA

Minimum Order Quantity:negotiation

Delivery Time:within 10 working days

Payment Terms:L/C

Place of Origin:CHINA

processing:finishing

Contact Now

Add to Cart

Site Member

Location:

Zhuzhou Hunan China

Address:

Jinshan Industrial Park, Hetang District, Zhuzhou City, Hunan Province, China

Supplier`s last login times:

within 14 hours

Product Details

Company Profile

Product Details

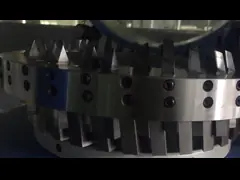

Slotting Milling Cutter

Definition

The tooth surface of the internal and external gears or racks, etc. processed by the gear shaping cutter according to the generating method or the forming method is called gear shaping. Gear shaping can process both straight and helical gears; hobbing can also process straight and helical gears, but gear hobbing is more efficient.

Principle

From the analysis of the principle of the gear shaping process, the

gear shaping cutter is equivalent to the meshing of a pair of

cylindrical gears whose axes are parallel to each other. A gear

shaper is essentially a gear with front and rear angles ground and

cutting edges.

Gear Shaping Slotting Milling Cutter Grey Finishing High Precision

Inquiry Cart

0