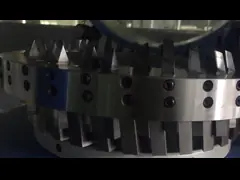

Full Radius Indexable Slotting Cutters finishing Carbide class A

Add to Cart

Indexable Carbide Insert Full Radius Slotting Cutters

Scope of application

(1) To process gears with shoulders and double or multiple gears

with narrow empty tool grooves, only gear shaping can be used. This

is because: Shaper knives require very little space to "cut out", w

hereas hob cutters interfere with large diameters. (2) For

processing herringbone gears without empty tool grooves, only tooth

shapers can be used; (3) For processing internal gears, only tooth

shapers can be used. (4) To process worm gear, only hobbing can be

used. (5) For machining helical cylindrical gears, both are

available. But hobbing is more convenient. When inserting helical

gears, the tool spindle of the gear shaper must be provided with a

helical guide rail to provide the helical motion of the gear

shaper, and a special helical gear shaper needs to be used, so it

is very inconvenient.

Ways to increase productivity

1. Increasing the circular feed can reduce the manoeuvring time,

but the circular feed is proportional to the yield during the idle

stroke. Therefore, the problem of the yield of the tool must be

solved.

2. Exploit the potential of the machine tool to increase the number

of reciprocating strokes and adopt high-speed gear shaping. The

number of reciprocating strokes per minute of some gear shapers can

reach 1200 to 1500 times/min, and can reach 2500 times/min. It is 3

to 4 times higher than the commonly used ones, which greatly

improves the cutting speed and reduces the maneuvering time

required for gear shaping.

3. Improve the tool parameters, improve the durability of the gear

shaper, and give full play to the cutting performance of the gear

shaper. If the W18Cr4V gear shaper is used, the cutting speed can

reach 60m/min; increase the rake angle to 15° and the relief angle

to 9°, which can increase the durability by 3 times; It can also

increase the durability by about 30%.