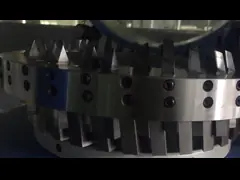

Small Indexable Slotting Cutter Carbide Tools Silver Class A

Add to Cart

Small Indexable Slotting Cutter Made In China

Process characteristics

Overview

Compared with gear hobbing, gear shaping has its own

characteristics in terms of processing quality, productivity and

application range.

productivity

When cutting gears with large modulus, the gear shaping speed is

restricted by the inertia of the reciprocating motion of the gear

shaping cutter spindle and the rigidity of the machine tool; the

cutting process has a time loss of idle travel, so the productivity

is not as high as gear hobbing. Gear shaping is more productive

than gear hobbing only when machining gears with small modules,

multiple teeth and narrow tooth widths.

Scope of application

(1) To process gears with shoulders and double or multiple gears

with narrow empty tool grooves, only gear shaping can be used. This

is because: Shaper knives require very little space to "cut out",

whereas hob cutters interfere with large diameters.

(2) For processing herringbone gears without empty tool grooves, only tooth shapers can be used;

(3) For processing internal gears, only tooth shapers can be used.

(4) To process worm gear, only hobbing can be used.

(5) For machining helical cylindrical gears, both are available. But hobbing is more convenient. When inserting helical gears, the tool spindle of the gear shaper must be provided with a helical guide rail to provide the helical motion of the gear shaper, and a special helical gear shaper needs to be used, so it is very inconvenient.