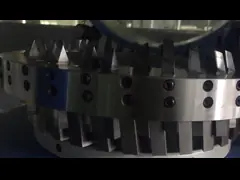

Grey Indexable Slotting Cutter Tool Carbide Bowl Shaped Gear

Add to Cart

Indexable Carbide Insert Slotting Cutters Made In Zhuzhou,China

Operation

In order to generate the relief angle and not affect the tooth

shape of the processed gear after regrinding, the shape of a

displacement gear is made in each section perpendicular to the axis

of the gear shaper. The displacement coefficient gradually

decreases from the front end to the rear end surface, and is

determined by positive to negative. Gear shapers are subject to

some limitations in use:

① Restriction of gear undercut: When the tooth top of the gear

shaper cuts into the involute tooth shape of the root of the gear

to be cut during the cutting process, it is called undercut. The

less the number of teeth of the gear to be processed, the greater

the possibility of undercut .

② The limitation of gear top cutting: Top cutting refers to the

phenomenon that the tooth top of the cut gear enters into the tooth

shape of the root of the gear shaper and is cut off.

③ Limitation of gear transition curve interference: When the gear

shaper is cutting teeth, it cannot cut out the involute tooth shape

on the entire tooth surface, and the gear root is the transition

curve. The smaller the number of teeth of the gear-shaping cutter

and the larger the coefficient of tooth profile deformation, the

longer the transition curve will be. If the tooth top of the paired

gear contacts the transition curve, interference will occur.

④ For the gear shaper for processing internal gears, the

restriction that the top cut does not occur during the radial

cutting process of the gear shaper should also be considered