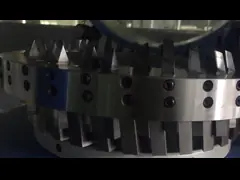

Polished Alloy High Speed Steel Lathe Tools Powder Metallurgy Hob

Add to Cart

Powder Metallurgy Hob

Application of powder metallurgy high speed steel:

The special and advanced smelting method of powder metallurgy

high-speed steel is an innovation of high-speed steel smelting,

which creates a new type of steel with properties between cemented

carbide and ordinary high-speed steel. The rise of powder

metallurgy high-speed steel has made new breakthroughs in tool

materials in the machinery manufacturing and processing industry.

As a new type of steel with excellent performance, it has gradually

been recognized, accepted and loved by people, and is playing an

increasingly important role in the machinery industry. .

Powder metallurgy high-speed steel has excellent toughness and

machinability, good red hardness, high compressive strength and

high wear resistance, as well as high alloy content, high purity,

no segregation, fine carbide particles and various It has the

characteristics of isotropy and homogeneity, so it has been widely

used. It can be used as a tool for processing non-ferrous metals

such as titanium and aluminum alloys, as a milling cutter, hob,

gear shaper, shaving cutter and other tools for processing gears,

and can also be used as a side milling cutter, forming milling

cutter and broach. It is also commonly used in twist drills,

machine taps, reamers, etc.; in the saw blade industry, powder

metallurgy high-speed steel is used as a band saw bimetallic steel

strip, as well as precision punching tools and punch dies and other

dies. Powder metallurgy high-speed steel is generally 4 to 8 times

the price of ordinary high-speed steel, so it is usually used to

manufacture sophisticated and complex tools or tools for CNC

machine tools. The performance of cutting tools made of powder

metallurgy high-speed steel is better than that of ordinary

high-speed steel, and the service life is higher than that of

ordinary high-speed steel (generally 2~3 times). The application

prospect in the tool industry is very promising, and it has

attracted more and more people's attention.