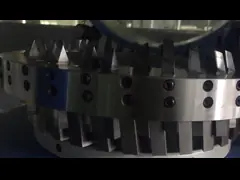

Round High Speed Steel Cutting Tools Silver Powder Metallurgy Gear Hob

Add to Cart

Powder Metallurgy Hob

Differences between cemented carbide steel and high-speed steel:

First, the performance of the two is different

1. Performance of cemented carbide steel: The cutting speed of

cemented carbide tools is 4 to 7 times higher than that of

high-speed steel, and the tool life is 5 to 80 times longer.

Manufacturing molds and measuring tools, the service life is 20 to

150 times higher than that of alloy tool steel. It can cut hard

materials of about 50HRC.

However, cemented carbide is brittle and cannot be machined, and it

is difficult to make integral tools with complex shapes. Therefore,

blades of different shapes are often made, which are installed on

the tool body or mold body by welding, bonding, mechanical

clamping, etc. .

2. Performance of high-speed steel: tool steel with high hardness,

high wear resistance and high heat resistance, also known as

high-speed tool steel or front steel, commonly known as white

steel. The quenching temperature of high-speed steel is generally

close to the melting point of the steel.

After quenching, it is generally necessary to temper 3 times

between 540 and 560 °C. Increasing the quenching temperature can

increase the red hardness of the steel. In order to improve the

service life of high-speed steel tools, the surface can be

strengthened, such as low-temperature cyanidation, nitriding,

sulfur-nitrogen infiltration, etc.

Second, the production process is different

1. The production of cemented carbide is to mix tungsten carbide

and cobalt in a certain proportion, pressurize them into various

shapes, and then semi-sinter. This sintering process is usually

carried out in a vacuum furnace. It is placed in a vacuum furnace

to complete the sintering, and the temperature at this time is

about 1300 to 1500 degrees Celsius.

Cemented carbide sintering molding is to press the powder into a

billet, and then enter the sintering furnace to heat to a certain

temperature (sintering temperature), keep it for a certain time

(holding time), and then cool it down to obtain a cemented carbide

material with the required properties.

2. The heat treatment process of high-speed steel is more

complicated, and it must go through a series of processes such as

quenching and tempering. Quenching is generally carried out in two

stages due to its poor thermal conductivity. First preheat at 800 ~

850 ℃ (to avoid causing large thermal stress), then quickly heat to

quenching temperature of 1190 ~ 1290 ℃ (the actual temperature of

different brands is different), and then oil cooling or air cooling

or gas cooling.

The factories are all heated by salt furnaces, and vacuum furnaces

are also widely used. After quenching, a part (about 30%) of

retained austenite remains in the internal structure and is not

transformed into martensite, which affects the performance of

high-speed steel. In order to transform the retained austenite and

further improve the hardness and wear resistance, it is generally

necessary to carry out 2 to 3 tempering times, the tempering

temperature is 560 ° C, and the temperature is kept for 1 hour each

time.