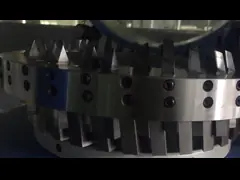

Arc Tooth Carbide Cutter Tools Cylindrical Wear Resistence

Brand Name:AOJIA

Minimum Order Quantity:negotiation

Delivery Time:within 10 working days

Payment Terms:L/C

Place of Origin:CHINA

material:carbide

Contact Now

Add to Cart

Site Member

Location:

Zhuzhou Hunan China

Address:

Jinshan Industrial Park, Hetang District, Zhuzhou City, Hunan Province, China

Supplier`s last login times:

within 14 hours

Product Details

Company Profile

Product Details

Carbide Arc Tooth Cutter

Arc tooth cutter is a kind of milling cutter, so How can I sharpen a milling cutter?

Before sharpening, the grinding wheel needs to be inspected. If it is found that the grinding wheel is beating, the cylindrical surface is irregular, and the fillet is too large, it needs to be trimmed. Generally, a grinding wheel corrector (diamond dresser, tooth dresser, etc.) can be used to dress the cylindrical surface of the grinding wheel, or a waste grinding wheel with relatively large abrasive grain hardness can be used for dressing. If the side plane of the grinding wheel is already uneven, the grinding wheel can be replaced.

Arc Tooth Carbide Cutter Tools Cylindrical Wear Resistence

Inquiry Cart

0